How to Maximize Trichome and Terpene Preservation During Cannabis Processing

Preserving terpenes and trichomes during cannabis processing is critical to maintaining product quality, potency, and consumer appeal. However, these delicate compounds are highly susceptible to degradation during processing due to factors like heat, oxygen exposure, and improper handling.

This article will explore the best practices for maintaining trichome integrity and terpene content during post-harvest cannabis processing, covering everything from trimming and drying to extraction and storage. For large-scale cultivators, ensuring these compounds remain intact is not just a matter of quality—it directly impacts the market value and efficacy of the final product.

Understanding Trichome and Terpene Preservation

The Importance of Trichomes

Trichomes produce and store cannabinoids and terpenes, playing a vital role in the plant’s potency. When trichomes are damaged or lost due to rough handling or improper processing, both potency and yield suffer, which reduces the value of the final product.

In large-scale cultivation, trichome retention is a key factor in maximizing returns. Advanced processing techniques and equipment selection can significantly impact trichome preservation, ensuring a more potent and marketable final product.

The Importance of Terpenes

Terpenes are highly volatile organic compounds responsible for the distinctive aroma and flavor of cannabis and potential therapeutic effects. They degrade quickly when exposed to heat, air, or light, making careful handling essential throughout every stage of processing.

Preserving cannabis terpenes is crucial because they contribute to the entourage effect, a synergistic interaction between different terpenes and cannabinoids that enhances the overall efficacy of cannabis products. When terpenes degrade, not only does the sensory profile suffer, but the therapeutic benefits may also be diminished.

Factors That Degrade Terpenes and Trichomes

Heat Exposure

Terpenes are highly volatile, with different compounds evaporating at varying temperatures. Some of the most delicate monoterpenes, such as terpinolene and α-pinene, begin to evaporate at temperatures as low as 70°F (21°C), while sesquiterpenes, such as α-humulene, can withstand slightly higher temperatures before degradation occurs. As processing temperatures increase beyond 100°F (38°C), terpene loss becomes more pronounced, leading to a diminished aroma and a weaker overall terpene profile in the final product.

Heat also affects trichome integrity by altering their structure and consistency. Trichomes are composed primarily of lipid-based resin containing cannabinoids and terpenes, and excessive heat can dry them out, making them brittle and more susceptible to breakage during handling. When trichomes become too fragile, they easily shear off during processing, leading to lower cannabinoid retention and reduced product potency.

To mitigate heat-related degradation, cultivators should ensure that processing environments maintain stable, controlled temperatures within the optimal range of 60-70°F (15-21°C). When equipment such as trimmers or mills are used, heat generation should be minimized through low-friction mechanisms and gentle processing speeds. Additionally, avoiding unnecessary exposure to warm air during drying and post-processing stages is crucial to preserving both volatile terpenes and the structural integrity of trichomes.

Light Damage

Light, particularly ultraviolet (UV) radiation, is one of the most damaging environmental factors affecting terpenes, trichomes, and cannabinoids. UV exposure accelerates the breakdown of these compounds, leading to diminished potency, altered chemical composition, and reduced overall product quality.

Studies show that trichome heads, which house cannabinoids and terpenes, are particularly vulnerable to photodegradation. Over time, exposure to UV light causes potency to degrade, causing some cannabinoids to turn into cannabinol (CBN), a cannabinoid with significantly reduced psychoactive effects.

Additionally, research into terpene degradation has suggested that monoterpenes, such as linalool, degrade more rapidly when exposed to direct sunlight. Though comprehensive cannabis-specific studies on terpene photodegradation are limited, studies on grapes and other aromatic plants indicate significant reductions in monoterpene levels following UV exposure. Given that cannabis shares many of the same terpenes, similar degradation patterns are likely to occur.

To mitigate light-induced degradation, cannabis should be stored in UV-resistant packaging such as amber glass jars, which block approximately 98% of harmful UV light. Vacuum-sealed opaque bags also provide protection from both UV light and oxygen exposure. Cultivators should store processed cannabis in cool, dark environments with minimal artificial lighting to prevent cumulative degradation.

Oxygen Exposure

Oxygen exposure leads to oxidation, which alters terpene profiles and degrades cannabinoids. Over time, oxidation results in diminished aroma and a harsher smoking experience. Research has shown that prolonged oxygen exposure can degrade potency, further impacting the overall quality of the final product.

Nitrogen flushing and vacuum-sealed packaging are effective methods for reducing oxygen exposure during storage and transportation. Storing cannabis in an airtight, low-oxygen environment helps maintain its original terpene profile and prevents premature cannabinoid degradation, ensuring longer-lasting freshness and potency.

Physical Handling

Excessive handling and mechanical agitation can cause trichomes to detach from the flower. Trichomes are delicate, and once they separate from the plant material, there is a measurable loss in cannabinoid and terpene content.

Hand-trimming, while favored by some craft growers, often results in significant trichome loss due to the repetitive physical manipulation of the buds. Automated trimming systems, like Mobius’ M108S precision-engineered trimmer, offer a gentler alternative that minimizes damage.

These mechanical trimmers operate with controlled cutting mechanisms that reduce unnecessary friction and agitation, preserving a greater percentage of the plant’s trichomes while maintaining efficiency at a commercial scale.

Improper Humidity Levels

Humidity plays a crucial role in terpene and trichome preservation. Low humidity levels below 50% can cause cannabis buds to become excessively dry and brittle. When this happens, trichomes lose their natural flexibility, making them prone to breaking off during handling and processing. Additionally, overly dry conditions can accelerate terpene evaporation, resulting in a less aromatic and flavorful product.

Conversely, humidity levels exceeding 65% create an environment conducive to mold, mildew, and bacterial growth. High moisture content promotes microbial contamination, which can degrade both terpenes and cannabinoids, potentially rendering the product unsuitable for sale. Mold growth is particularly concerning in commercial cannabis operations, as it can compromise entire batches and lead to regulatory compliance issues.

Maintaining an optimal drying and curing environment with humidity levels between 55% and 60% RH ensures that cannabis retains its terpene profile and structural integrity while minimizing microbial risks. Proper environmental control through specialized curing rooms, dehumidifiers, and hygrometers helps cultivators maintain these ideal conditions.

Preserving Potency for Downstream Processing

The preservation of terpenes and trichomes during initial processing has significant implications for secondary and downstream cannabis processing. Whether the final product is intended for extraction, infused products, or premium cured flower, early-stage degradation of these compounds results in diminished quality at every subsequent step.

For extraction-based products, loss of terpenes in the initial handling stages leads to a final extract with a weaker aromatic profile and reduced therapeutic potential. Terpene-rich extracts, such as live rosin or high-terpene full-spectrum extracts (HTFSE), depend on careful processing to maintain their potency. Trichome degradation also reduces the overall cannabinoid yield, impacting efficiency in solventless and solvent-based extraction methods alike.

For cured flower or pre-rolls, early trichome loss affects potency, bag appeal, and combustion quality. Without intact trichomes, flower lacks the sticky resin that enhances consumer perception of freshness and potency. Pre-rolls made from improperly handled material may burn inconsistently due to reduced resin content, leading to a subpar user experience. By prioritizing terpene and trichome preservation during trimming, drying, and sorting, processors ensure that every downstream product — whether a concentrate, pre-roll, or premium flower — maintains maximum potency and consumer appeal.

Best Practices for Preserving Terpenes and Trichomes During Processing

Trimming

Trimming is an important step in post-harvest cannabis processing that directly impacts the preservation of terpenes and trichomes. Improper trimming methods can lead to excessive trichome loss, reducing both potency and overall product quality.

Hand-trimming, while sometimes preferred for artisanal batches, often results in unnecessary handling, which can knock off delicate trichome heads and expose cannabis to oxygen and light for extended periods, accelerating terpene degradation.

Precision trimming machines provide a more consistent and efficient alternative. These automated systems are designed to reduce mechanical agitation, preserving more trichomes compared to manual methods. By using low-friction cutting mechanisms, these machines ensure minimal damage to delicate trichomes while maintaining high throughput, making them ideal for large-scale commercial operations.

Another effective approach is processing plant material at cooler temperatures — between 60° and 70°F (15-21°C). This method helps reduce terpene evaporation by keeping the cannabis cooler, thereby preserving volatile aromatic compounds. Additionally, trimming in cool temperatures can prevent trichomes from becoming too sticky or clumping together, ensuring a more uniform and efficient trim.

Drying

Drying is one of the most critical steps in cannabis processing, directly impacting terpene retention and trichome integrity. The ideal drying environment maintains temperatures between 60-70°F (15-21°C) with humidity levels stabilized at 55-60%. This controlled environment ensures that moisture is removed at a gradual pace, preventing terpene evaporation and minimizing stress on the trichomes. Rapid drying, often caused by excessive airflow or high temperatures, leads to significant terpene loss, degrading the aroma and overall quality of the final product.

A slow drying process lasting 10-14 days in a dark, well-ventilated space is recommended to preserve volatile terpenes. Darkness is crucial since exposure to light — especially UV light — can degrade cannabinoids and terpenes, while proper air circulation prevents mold growth without over-drying the plant material. Using specialized drying rooms with temperature and humidity controls helps commercial cultivators achieve consistent, high-quality results.

Hot-air drying methods, such as using direct heat or excessive ventilation, should be avoided. These techniques can strip moisture too quickly, resulting in brittle cannabis buds that are prone to trichome breakage. Instead, using indirect airflow systems that promote even moisture loss across the flower without causing turbulence helps maintain terpene integrity.

Curing

Curing is a post-harvest process that allows for the gradual stabilization of moisture content, enhancing terpene retention and improving the overall quality of the cannabis flower. Unlike drying, which focuses on removing excess moisture from the outer layers of the bud, curing enables moisture to redistribute evenly throughout the flower, preventing terpene degradation and preserving cannabinoid potency. The recommended curing period ranges from two to four weeks, depending on the initial moisture content and environmental conditions.

For optimal curing, cannabis should be stored in airtight glass jars or other non-reactive, food-grade containers that prevent oxidation while allowing cultivators to regulate humidity levels. During the first two weeks of the curing process, the jars should be “burped” daily, meaning they are opened for a few minutes to release built-up moisture and replenish oxygen levels. This step is essential to preventing mold growth while allowing the buds to reach an ideal balance between dryness and retained moisture.

Properly cured cannabis retains a richer terpene profile, leading to a smoother smoking or vaping experience with more pronounced flavors and aromas. In contrast, improperly cured cannabis can taste harsh and lose much of its aromatic complexity due to excessive terpene evaporation. Maintaining ideal temperatures (60-70°F) and humidity levels (50-60%) helps preserve both trichome integrity and volatile terpenes, ensuring that the final product maintains its full-spectrum effects and a rich aromatic profile.

Preserving Potency During Post-Cure Processing

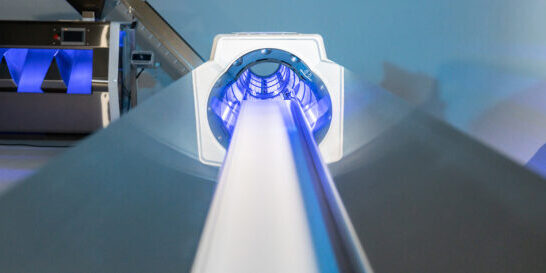

Milling

Milling is a crucial step in cannabis processing, particularly when preparing material for extraction or pre-rolls. The challenge with milling is that excessive friction and high-speed grinding can generate heat, leading to terpene volatilization and trichome breakage. Using low-impact milling techniques with perforated screens helps reduce excessive force and heat buildup, preserving more delicate terpenes and cannabinoids. Selecting the appropriate grind size is also essential, as over-milling can break trichome heads, releasing their contents prematurely and leading to terpene loss before extraction or final product formulation.

Extraction

The extraction process is where many terpenes are at risk of degradation, especially in solvent-based methods that expose plant material to high temperatures or aggressive chemical interactions. Solventless extraction methods, such as rosin pressing and bubble hash extraction, provide a gentler approach that preserves more of the original terpene profile. Fresh-frozen extraction, in which cannabis is frozen immediately after harvest, helps retain the highest levels of volatile terpenes by preventing oxidative degradation before processing begins. This method is particularly valuable in producing live rosin and high-terpene full-spectrum extracts (HTFSE) that prioritize flavor and aroma preservation.

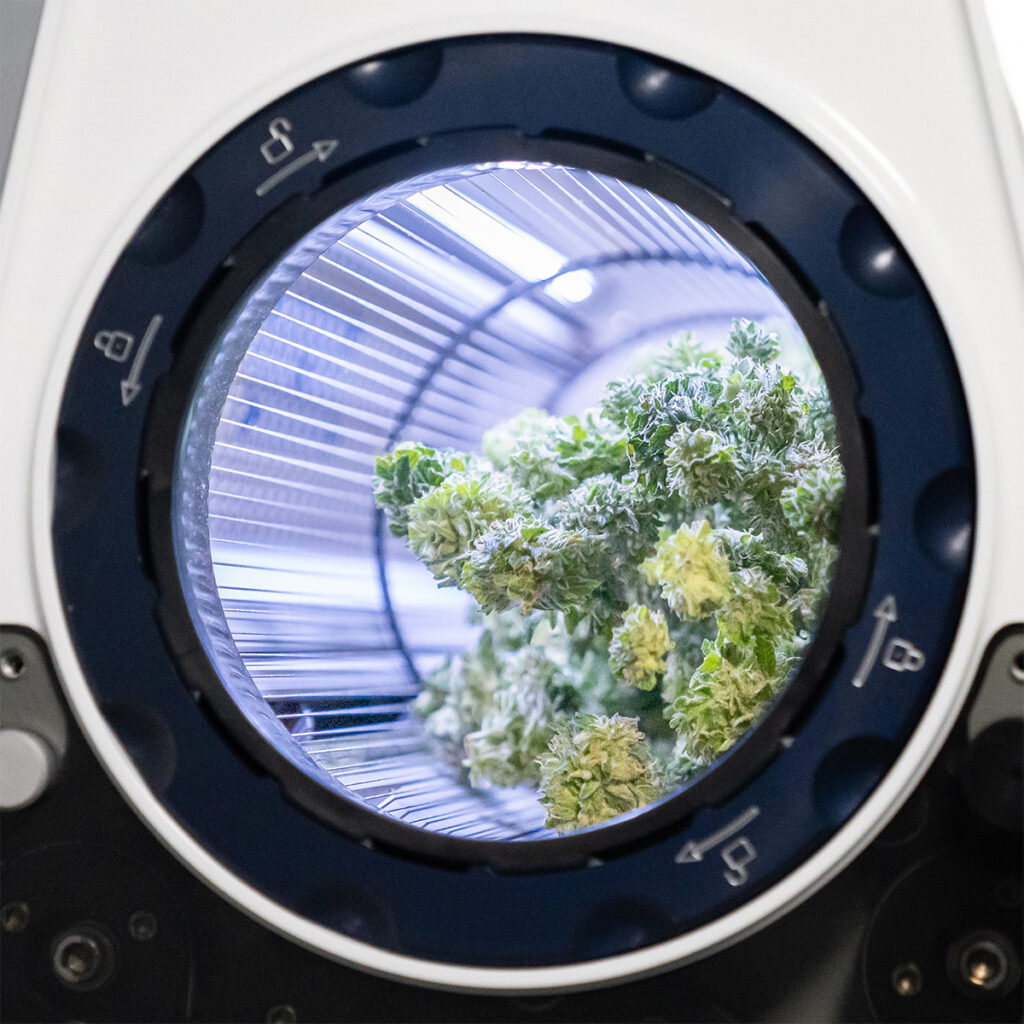

Sorting

Sorting is another point where trichomes can be lost due to physical impact and too much agitation. Gentle sorting techniques that minimize unnecessary movement of the cannabis flower reduce the risk of breaking trichome heads. Using food-grade stainless steel equipment is also recommended, as it helps prevent contamination and static buildup, which can cause trichomes to stick to surfaces instead of remaining intact within the final product. Proper sorting also ensures that different grades of flower are separated efficiently, allowing processors to allocate the highest-quality material for premium products while directing lower-grade trim for extraction processes.

Storage and Packaging Practices for Peak Freshness and Potency

Use Airtight, UV-Resistant Containers

Proper storage begins with selecting the right containers. Glass jars with airtight seals or vacuum-sealed bags protect cannabis from oxygen exposure, which can cause oxidation and terpene loss to accelerate. UV-resistant packaging, such as amber glass, is particularly effective in blocking harmful light wavelengths that degrade cannabinoids and terpenes over time. For commercial-scale storage, materials like high-barrier mylar bags with nitrogen flushing provide an added layer of protection against environmental degradation.

Implement Nitrogen Flushing

Nitrogen flushing is a widely used technique in cannabis packaging to replace oxygen within a sealed environment. By displacing oxygen, nitrogen prevents oxidative degradation of terpenes and cannabinoids, extending shelf life and preserving the original terpene profile of the flower. This method is commonly used in vacuum-sealed bags and pre-packaged cannabis products to maintain peak freshness and potency for longer periods.

Maintain Proper Storage Temperatures

Temperature control is a crucial factor in preventing terpene volatilization and trichome degradation. Cannabis should be stored in a cool, dark environment with temperatures maintained between 40-60°F (4-16°C). Storing cannabis at higher temperatures can accelerate terpene evaporation, while excessively cold conditions may cause trichomes to become brittle and break off. Maintaining stable temperatures within this optimal range ensures that the cannabis retains its full potency, flavor, and aromatic complexity over time.

Optimizing Cannabis Processing for Maximum Potency and Quality

Preserving terpenes and trichomes during cannabis processing is essential for maintaining product quality, potency, and consumer appeal. By implementing best practices in trimming, drying, curing, and storage, cultivators can significantly reduce terpene and trichome degradation. Investing in precision-engineered equipment and maintaining optimal environmental conditions ensures a superior final product that meets the demands of high-end commercial markets.

For more information on optimizing your cannabis processing techniques, contact Mobius today or explore our range of precision commercial equipment.