End-to-end

AUTOMATION

Put profitability on autopilot with the full suite of automated processing equipment from Mobius.

Cut your operating costs. Increase product quality and shield yourself against regulatory threats with GMP-ready machines built to industrial standards.

The Mobius Cannabis Automation Suite moves and processes your marijuana crop flawlessly — with fewer chances for human error or contamination — giving you faster speed to market, better employee retention, and a solid foundation for growth.

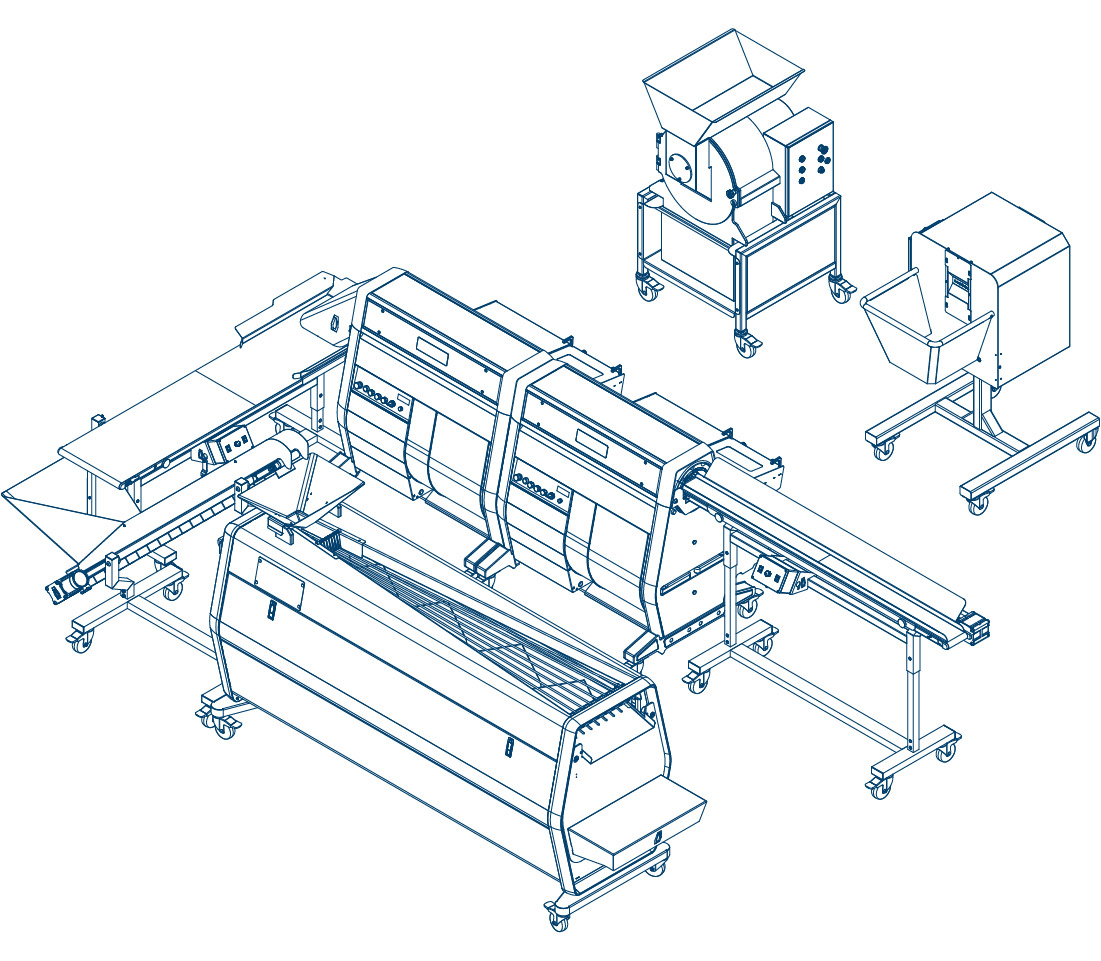

MBX Bucker

Remove cannabis flowers from their stems without compromising the buds, and retain the potency of your cannabis product while doing so.

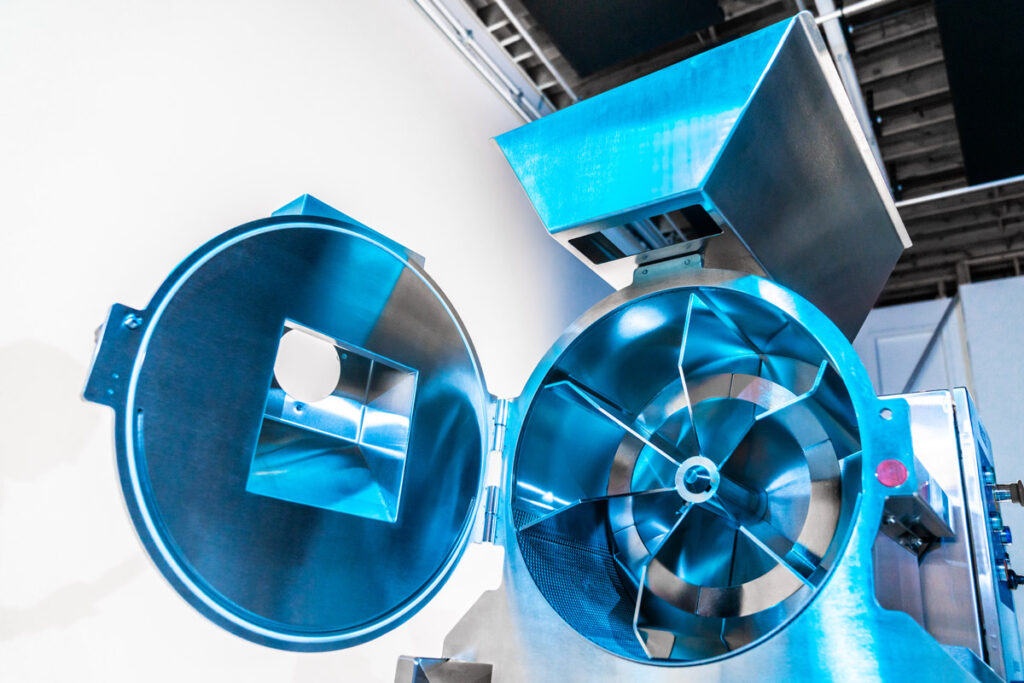

M210 MillM210 Mill

Grind cannabis flower and trim for precision-milled extracts and pre-rolls. Find the perfect grind for your product, whether it be for medical marijuana, dispensaries, extraction, or any other use.

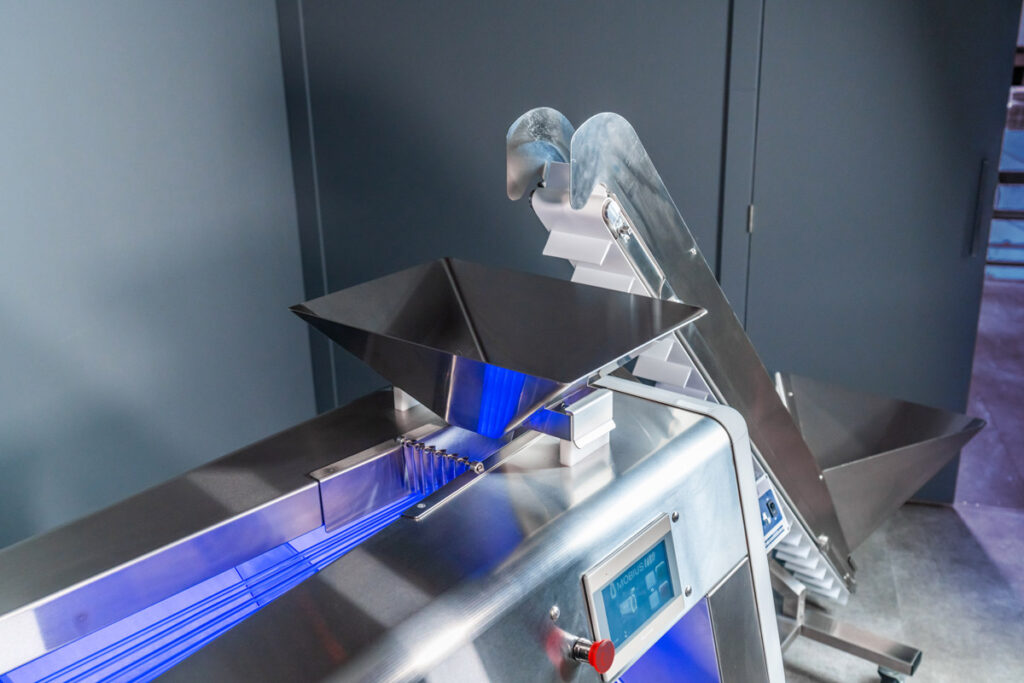

Infeed ConveyorInfeed Conveyor

Improve trimmer feed rates and consistency by utilizing the Mobius Infeed Conveyor to feed untrimmed flower into the M108S Tandem Trimmers. It is a great option for cultivators looking to ramp up their cannabis production.

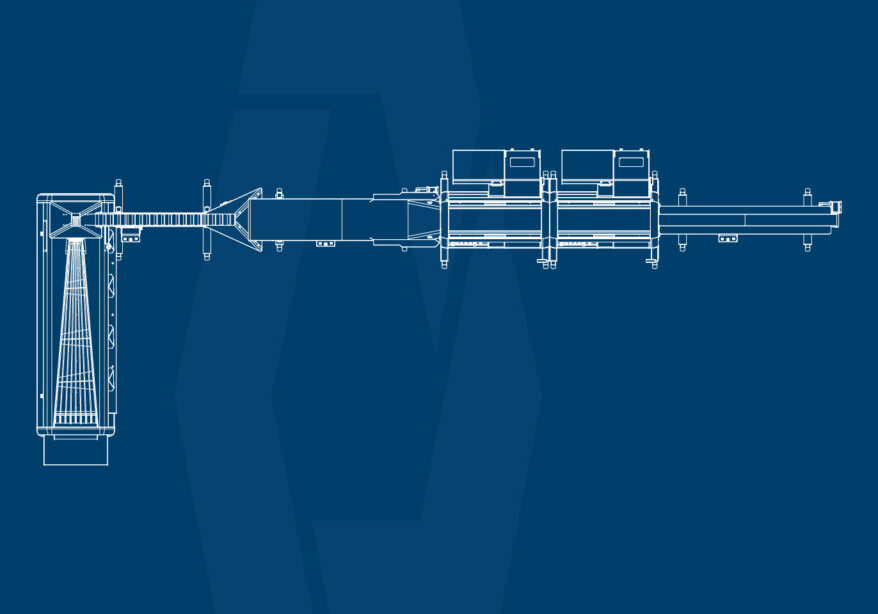

Tandem M108S TrimmersTandem M108S Trimmers

Deliver hand-trim quality flower at a commercial scale with two M108S Trimmers. A powerful tool for any cannabis cultivation company post-harvest.

Outfeed ConveyorOutfeed Conveyor

Perform continuous quality control while moving trimmed flower to the Mobius Autofeed Conveyor.

Autofeed ConveyorAutofeed Conveyor

Automatically feed trimmed cannabis flower into the M9 sorter. No hands required!

M9 SorterM9 Sorter

Continuously sort cannabis and hemp flower by size to streamline post-harvest processes such as categorizing, weighing, and packaging.

Supercharge your cannabis production

Integrate Bloom AI, the most advanced computer vision system in the cannabis industry.

Free Workflow Design Services

How It Works

Step 1

Connect With Mobius

Fill out the design form below, and we’ll pair you with an Automation Specialist from our in-house team.

Step 2

Get Expert Analysis

We'll review your information and identify automation configurations to reduce operating expenses and help your cannabis business grow.

Step 3

White-Glove Service

Following the purchase of an Automation Suite, we'll send a specialist to your facility to implement the cannabis equipment and onboard your team.

Financial Flexibility

Mobius offers payment plans to fit most business plans. Flexible terms provide you with an affordable way you expand your post-harvest operations.

Increase Profit

Improve your profitability by reducing harvest labor costs and time to market.

Connect with a Mobius harvest expert to discuss your potential savings.

Labor Summary

Harvest Size Per Week (lbs) |

Total Staff

|

Hand Trim Cost |

Total Staff

|

M108s Tandem Trim

|

Cost Savings per Harvest |

Automation Suite ROI

|

|---|---|---|---|---|---|---|

| 1000 | 133 | $106,667 | 7 | $3,376 | $103,291 | 1.72 |

| 800 | 107 | $85,333 | 7 | $2,700 | $82,633 | 2.15 |

| 600 | 80 | $64,000 | 7 | $2,025 | $61,975 | 2.86 |

| 400 | 53 | $42,667 | 7 | $1,350 | $41,317 | 4.3 |

| 200 | 27 | $21,333 | 7 | $675 | $20,658 | 8.59 |

| 100 | 13 | $10,667 | 7 | $338 | $10,329 | 17.18 |

It's one thing to trim two plants. It's a whole other thing to trim 4,000 plants. That's where I really start to get happy about the Mobius equipment and what it's done for us.

–

IAN MCFADDEN

SVP QUALITY & OPERATIONS, ALEAFIA HEALTH

GMP Solutions

Step 1 Cleaner

Safely, and effectively clean your cannabis equipment with GMP Solutions Step 1 Cleaner. This powerful formula removes tough resin buildups and soils, helping you meet your GMP cleaning requirements.

FAQs

What kind of efficiency improvements can cannabis growers expect with Mobius Trimmer's automation technology?

With the Mobius Automation Suite, processors will reduce labor and operating costs during post-harvest processing. Production capacity and processing capabilities multiply, and minimized downtime during processing allows for greater efficiency. Check out some of Mobius’ case studies for how our automation equipment has helped other facilities.