Download the GMP Guide

Enter your email to download the full version of our Guide to GMP-Certified Post-Harvest Processing including:

- GMP checklists for sanitation, equipment, and personnel

- Expert guidance on how to prepare for GMP certification

- Best practices for equipment maintenance, sanitation, and assessment

- A sample GMP audit form to begin the planning process

Download GMP Guide

Fill out the form to download the Mobius Cannabis & GMP Guide to GMP-Certified Post-Harvest Processing

"*" indicates required fields

Section 1:

What is GMP?

GMP stands for Good Manufacturing Practice.

GMP is a set of rules and procedures related to the handling, cleaning, quality assurance, and packaging processes in manufacturing facilities and the products they make.

Regardless of the licensing authority, the category under which cannabis is produced (medical or recreational use), or the form of the end-product (flower, concentrate, edible, etc.), cannabis is considered a drug and is subject to the various regulations and guidelines governing drugs. Many jurisdictions around the world, including the European Union (EU), Canada, USA, Australia, New Zealand, and Israel, require the application of Good Manufacturing Practices (GMP) in the manufacturing of drugs intended for their marketplace. Mutual Recognition Agreement (MRA) countries define GMP as the part of quality assurance that ensures that drugs are consistently produced and controlled in such a way as to meet the quality standards appropriate to their intended use, as required by the marketing authorization.

Essentially, GMP ensures that a food or drug product is safe for human consumption.

How Does GMP Apply to the Cannabis Industry?

Whether cannabis is being grown and produced for local (in-state or in-country) consumption, or for export abroad, virtually all cannabis legislation requires some level of production quality assurance, though it’s not always GMP.

As GMP is the standard that pharmaceutical companies apply to the production of their medicines, the production of medical-grade cannabis should not be treated differently. The application of GMP to the harvesting and production of cannabis ensures that the end-user knows what they buy is safe to consume and consistent with each purchase.

WHAT ARE THE CONSEQUENCES OF NOT APPLYING GMP?

While there are many jurisdictions without GMP requirements for cannabis products, cannabis regulations in the future will likely require GMP certification for licensed manufacturers to receive and maintain their licenses.

Businesses that fail to maintain GMP certification risk losing valuable sales opportunities as more consumers will expect to see the certification on their products. In business-to-business cannabis sales, many buyers already require GMP certification from any cannabis manufacturer they source product from.

Section 2:

GMP Requirements for Post-Harvest Processing

There are many requirements that constitute GMP, but this guide focuses on the aspects of GMP that relate to the post-harvest processing of cannabis. Citations are sourced from the European Commission’s EudraLex – Volume 4 – GMP Guidelines and from Canada’s GMP Guidelines, both of which are harmonized with the requirements of other MRA countries.

At a high level, the basic requirements of a GMP program for the post-harvest processing of cannabis can be summarized as follows:

- Manufacturing processes are clearly defined and controlled to ensure consistency and compliance with approved specifications and procedures.

- Critical steps of manufacturing processes and significant changes to the process are validated.

- All necessary key elements for GMP are provided, including the following:

- Qualified and trained personnel.

- Adequate premises and space.

- Suitable equipment and services.

- Correct materials, containers, and labels.

- Approved procedures and instructions.

- Suitable storage and transport.

- Instructions and procedures are written in clear and easy-to-understand language.

- Operators are trained to carry out and document procedures.

Equipment

The equipment with which drugs are fabricated, packaged/labeled, or tested shall be designed, constructed, maintained, operated, and arranged in a manner that:

- Permits the effective cleaning of its surfaces.

- Prevents the contamination of the drug and the addition of extraneous material to the drug.

- Permits it to function in accordance with its intended use.

Personnel

Every lot or batch of a drug shall be fabricated, packaged/labeled, tested, and stored under the supervision of personnel who, having regard to the duties and responsibilities involved, have had such technical, academic, and other training as the Director considers satisfactory in the interests of the health of the consumer or purchaser.

Sanitation

Every person who fabricates or packages/labels a drug shall have a written sanitation program that shall be implemented under the supervision of qualified personnel. The sanitation program shall include:

- Cleaning procedures for the premises where the drug is fabricated or packaged/labeled, and for the equipment used in the fabrication or packaging/labeling of the drug.

- Instructions on the sanitary fabrication and packaging/labeling of drugs and the handling of materials used in the fabrication and packaging/labeling of drugs.

CLEANING VALIDATION GUIDELINES

Once you have the equipment, personnel, and sanitation programs in place, it is necessary to validate the cleaning procedures that are employed. The following are the GMP guidelines for cleaning validation.

access valuable information about equipment, sanitation, personnel, and cleaning validation guidelines.

Section 3:

Getting Operations GMP-Ready

Preparation Steps

The previous sections went into greater detail on the various requirements under GMP. While this may seem overwhelming, we’ve outlined four things you can do to get your post-harvest cannabis operations on the right track and GMP-ready.

- DOWNSIZE & DEEP CLEAN

- KEEP MAINTENANCE RECORDS & INSPECT YOUR EQUIPMENT

- TRAIN YOUR TEAM & ENSURE COMPREHENSION

- CLEAN WELL & ON A SCHEDULE

access valuable information about equipment, sanitation, personnel, and cleaning validation guidelines.

Section 4:

ADDITIONAL RESOURCES

Edible Cannabis Products & HACCP

Hazard Analysis Critical Control Points (HACCP) is an internationally recognized system used to enhance food safety throughout the food chain. A HACCP system consists of prerequisite programs and a HACCP plan. Prerequisite programs are outside the HACCP plan but still fall within the HACCP System. They keep potential hazards from becoming serious enough to adversely impact the safety of foods produced. GMP is an example of a prerequisite program. The purpose of the HACCP plan, or food safety plan, is to prevent, eliminate or reduce potential food safety hazards to an acceptable level.

When making any cannabis-containing edible product, many raw ingredients, including cannabis, will be required. If the company producing the edible is following HACCP, they will implement a prerequisite program to ensure that incoming materials (i.e. the raw ingredients) are safe and of good quality. Procuring cannabis from a GMP-certified supplier would meet this prerequisite by verifying the quality of this particular input material, thereby providing justification for not adding the processing of cannabis to the HACCP Plan.

Using cannabis from a GMP-certified supplier to produce an edible product does not negate the need for a HACCP plan, but it does eliminate the need to consider the cannabis ingredient itself as a potential source of hazard that must be addressed in the HACCP Plan.

Unlock the expert knowledge in the full GMP Guide download, complete with a comprehensive table outlining GMP requirements for equipment, cleaning, and operational procedures.

Using Mobius Equipment in a GMP-Certified Environment

Previously, one of the major obstacles for a licensed cannabis producer that sought GMP certification was how to qualify their processing equipment, particularly trimming equipment, into that GMP workflow. Most cannabis processing equipment is notoriously difficult to clean, which makes it more challenging, if not impossible, to consistently meet the requirements of a GMP cleaning validation protocol.

The Mobius Automation Suite of cannabis processing equipment is different. It has been designed from the ground up with GMP in mind:

- All plant-touching parts of Mobius machines are smooth and made of non-toxic, corrosion-resistant, non-reactive materials, capable of withstanding repeated cleaning.

- All plant-touching parts of Mobius machines are accessible and/or removable for cleaning and can be effectively cleaned with non-toxic detergents or just water alone.

- Mobius machines do not have any hoses or hidden parts, which are exceptionally difficult to clean

and have the potential to harbor microorganisms. - SOPs for Mobius machines are simple and straightforward, ensuring consistency in operations

and products.

Get an in-depth look at how one specific piece of equipment, the Mobius M108S Trimmer, addresses each one of the trimming-related GMP requirements.

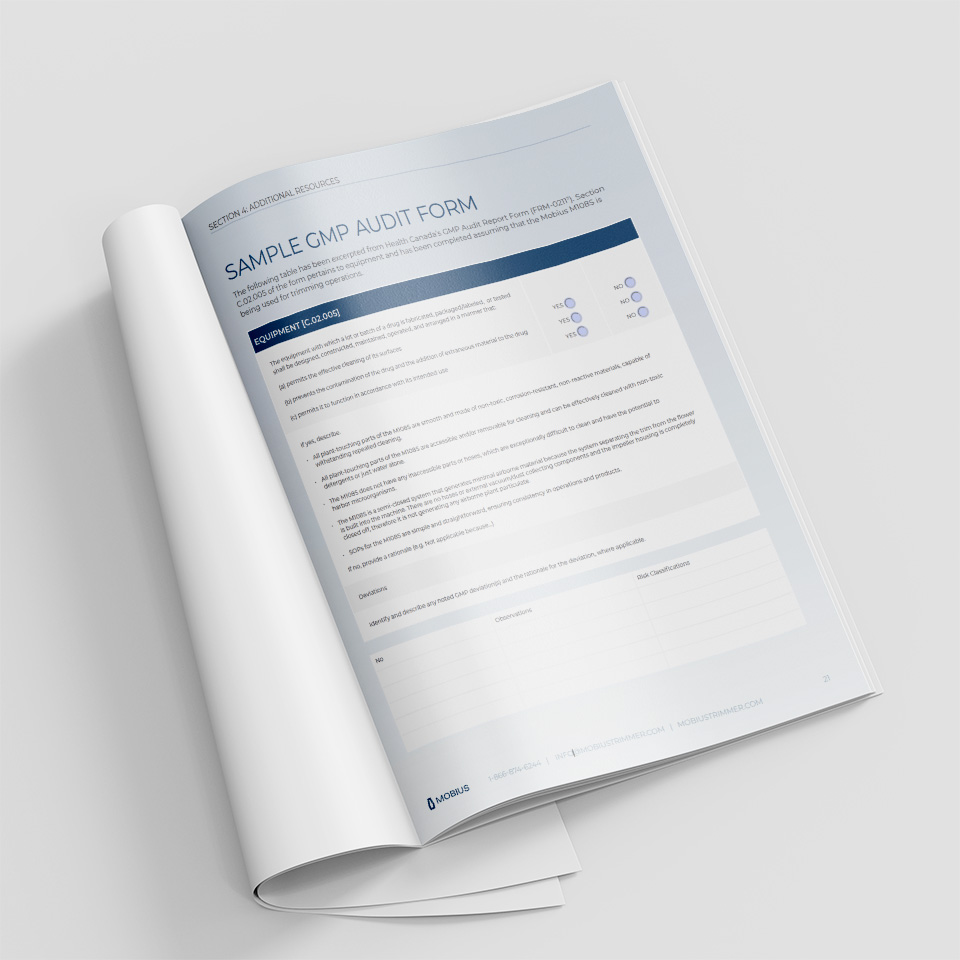

Sample GMP Audit Form

Access the complete guide with valuable information and sample forms that are only available in the exclusive PDF Download.

Recommended Reading

Cleaning Fundamentals

Keeping equipment and processing spaces clean is the best preventative maintenance action in order to keep operations in peak condition and maximize the service life of your equipment. Cleaning will remove most germs, dirt, and impurities from surfaces while sanitizing reduces the remaining germs on surfaces after cleaning to levels that public health codes or regulations consider to be safe.

Business News Network

While not specifically a cannabis-industry source, they provide more and better coverage of the industry than just about anyone. Not only that, much of their coverage includes interviews and videos. Their content is from a business perspective (of course), and does tend to focus on Canadian companies, but that’s because they’re the biggest players in the game. Check out their Marijuana News page to stay up-to-date.

Marijuana Business Daily (AKA MJBizDaily)

Marijuana Business Daily provides a good, focused look at not only the business, but also cannabis policy and political news from around the world. They are a news aggregator, so often gathering stories from external sources, but they do write their own deep coverage of important issues. A recent example was their province-by-province series looking at the policy rollouts here in Canada, and great coverage of the recent changes in California.

The Cannabist

It’s for all things cannabis, not just for news. Their news section is great though. They mix in the more entertaining/less informative stories with the hard coverage, which is great for a lunch-break read (ex: Grandparents caught in Nebraska with 30lbs of pot gummies in the car). They’re located in Denver, so carry a lot of Colorado-centric stories, but they still have coverage from around the US and Canada.

Marijuana.com

From the folks behind Weedmaps, Marijuana.com provides more feature writing than many of the other sites, thanks to scribes Monteray Bud and Duke London. Their coverage volume is lower than most on this list, with maybe 3-4 exclusive pieces per week, but the quality is very good.

Lift.co

Lift is known for their strain reviews, but the news section on Lift’s site is getting better and better. They have a substantial list of contributors, including many that hold full-time positions at major players in the cannabis industry. They don’t aggregate stories from other sites, which is refreshing. Since they’re a Canadian company, much of the content is Canadian-focused, but so are we, so we’re okay with that.

GMP & Marketing

Being able to include GMP as part of your brand messaging is just one more benefit of seeking this level of certification, but a valuable one. Read more about how the GMP certification for cannabis has become a marketing tactic to leverage with investors and consumers.