Milling Temperature

Mobius provides exceptional white-glove customer service to every client. Your investment is backed by a one-year warranty and a satisfaction guarantee.

Even years later, we're here to support you, whether it's troubleshooting or fine-tuning your production floor for optimal performance.

This case study was performed at the facility of a long-term Mobius customer encountering performance changes with their M210 Mill.

THE EXPERIMENT

On November 1, 2023, Mobius Automation Specialists visited the client's facility to address their milling concerns. Mobius devised an experiment to determine if operating the mill at lower room temperatures could correspond with less screen smearing.

Two room temperature variants (4°C/40°F and 10°C/50°F) were to be tested, each with two product variants: one at ambient room temperature and with frozen material (frozen in chest freezer and held in coolers until milled).

Product Details:

Moisture Content: 7-9%, averaging 8.5%

Characteristics: 0.2-0.5g bud size, with small pointy stems prior to milling. Dense buds, greasy to the touch, buds do not break down from small bud size with hand agitation.

Test Design:

Process material in the Mobius M210 Mill in 2kg batches at two room temperature variants (4°C/40°F and 10°C/50°F). Rasp screens were replaced and the rotor was cleaned between tests.

The following variables were recorded to gauge success:

- Throughput rate

- Screen smear

- Particle size distribution

- Presence of kief balls/packing

- Time spent cleaning after processing

THE Solution

Before

After milling at ambient room temperature: evident screen smear on the 2mm rasp screen.

After

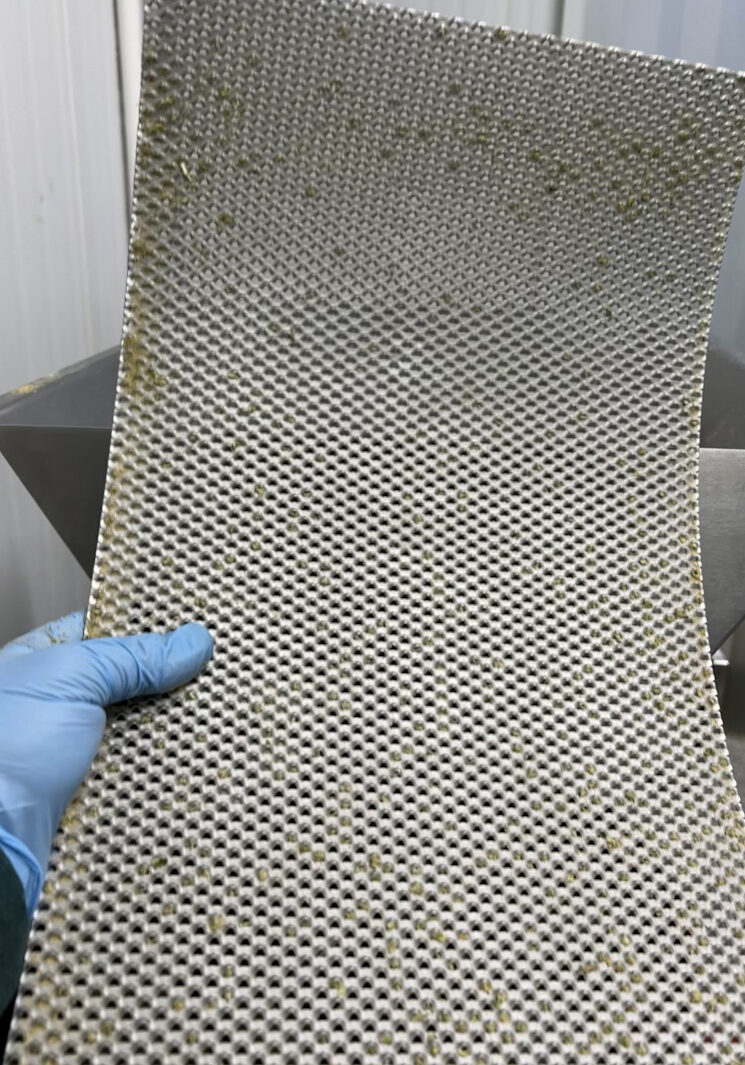

After milling at 4°C/40°F room temperature: no visible screen smear on the 2mm rasp screen.

Lowering the temperature of the room in which the mill was being operated to 4°C/40°F (regardless of using room temperature or fresh frozen cannabis) saw improvement in all variables:

- The final material showed zero signs of stems that would puncture a pre-roll tube.

- Material particle size was consistent to the naked eye.

- Kief was very fine and powdery, easy to brush into the tote from build-up areas.

- A visual inspection of the machinery after processing saw no resin build-up on the screen, rotor, or any other components. Any material left in the apertures of the screen was easily brushed through the screen with a hand.

- Small build-up was noted on the edges of the screen.

Experiments at 10°C/50°F and ambient room temperature saw a significant amount of un-milled product remaining in the chamber, screen clogging, kief packing/balling on the rotor, and an overall increase in processing time.

Our client was confident that their milling issues could be solved by lowering the temperature of the room in which the mill was being operated, and that results at 4°C/40°F with room temperature and frozen material were much preferable to the results at 10°C/50°F, and especially in comparison to ambient room temperature.