Everything You Need To Know About Cannabis Extraction Equipment

If you run a commercial cannabis operation and are interested in adding cannabis extract to your product list, it’s important to know everything you can about cannabis extraction equipment before you begin. Whether you’re new to the cannabis industry or have been cultivating cannabis for years, providing cannabis extracts to prospective clientele is a game changer for building or expanding your business.

Whether in the form of tinctures, wax, rosin, shatter, or hash, cannabis extracts are some of the most popular cannabis products in today’s legal market. In 2021, the global cannabis extract market was valued at $2.74 billion (USD) and, it’s expected to grow exponentially. According to a recent market analysis report, it’s estimated the extract market will grow at a 20.6% compound annual growth rate (CAGR) through 2030.

Entrepreneurs interested in profiting in today’s legal cannabis industry understand that cannabis oil and other extracts can be a serious boon for their business. If you’re interested in becoming a successful player in the cannabis extract game, the following is everything you need to know about the best cannabis extraction equipment to get you started.

What Is Cannabis Extraction Equipment?

Before any cannabis concentrate, oil, or CBD tincture becomes a product sold online or at a dispensary, it must first be extracted from the cannabis plant itself. The way to do this is with cannabis extraction equipment.

With several types of extraction equipment available, the type of extraction method you choose ultimately depends on your goals and the end product you desire to produce.

Steps To Take Before Investing

A cannabis extraction system is a big investment, and there are a few important things to determine before committing to something specific.

Will You Be Processing Hemp, Marijuana, or Both?

Determining whether you’ll be extracting from hemp, marijuana, or both is the first step in establishing the best extraction system to meet your business needs. There are different production and processing conditions between each type, and knowing what type of plant will be processed is the foundation for determining the type of extraction equipment you’ll need.

Which Solvent Do You Prefer For Extraction?

The substances and methods used during the extraction process will largely determine extract quality and composition. With that, it’s important to determine the type of solvent you’d like to use. Ultimately, this will influence the type of extraction equipment you purchase.

What End Product Do You Want To Produce?

The type of product you want to produce is another key point to consider and will largely determine the type of extraction equipment that will best serve your needs. Extracting just cannabis oil will require different extraction equipment than products like rosin, hash, budder, shatter, and wax

What Are The Regulations And Laws In Your Area?

While hemp is legal at the federal level and marijuana is legalized in several states, there are no clear FDA regulations for the extraction of cannabis concentrates. The regulation of cannabis extraction and types of solvents permitted is therefore determined by individual state law. Understanding regulations and laws in your area is imperative when choosing cannabis extraction equipment.

Types Of Cannabis Extraction Equipment

Once you’ve asked yourself the above questions, you can begin to explore the following different extraction system options:

Ethanol Extraction

Ethanol is versatile and can be used to create a variety of hemp and cannabis products. Ethanol is one of the cleanest solvents, as it doesn’t leave any residual solvents in the final product when extraction is performed correctly. Ethanol extraction involves soaking plant material in ethanol, which naturally pulls cannabinoids and terpenes from the plant material. It can be done under warm or cold temperatures. Cold ethanol extraction, or cryogenic ethanol extraction, freezes undesirable compounds like water, fats, and waxes so they don’t dissolve into the ethanol. It reduces the need for winterization and is considered highly efficient. Warm ethanol extraction typically involves special equipment and involves passing warm ethanol several times over the plant material. After extraction is completed, further steps such as winterization are required to remove unwanted plant compounds. Ethanol is a great choice for small-scale operations because it can produce a variety of cannabinoid products. For those with large-scale operations, ethanol extraction is an excellent option for isolating specific cannabinoids and terpenes.

CO2 Extraction

CO2 extraction is one of the safest, most popular methods used for extracting both cannabinoids and terpenes. CO2 extraction involves using pressurized carbon dioxide to pull cannabinoids from the plant material and leaves no residual solvents. Because of this, CO2 is widely used in food processing and essential oil extraction. There are various options for CO2 extraction equipment, making it perfect for starting small and scaling up as business expands.

Hydrocarbon Extraction

For those interested in producing strain-specific extracts such as live resin, shatter, or wax, hydrocarbon extraction is the best extraction equipment option. Hydrocarbon solvents include butane, propane, and hexane, all of which are ideal for preserving a particular strain’s unique flavor profile, something that is highly important to some cannabis connoisseurs. Hydrocarbon extraction involves combining plant material with the selected solvent, where cannabinoids and other compounds are stripped from the plant material. Following initial extraction, the oil is further refined and then passed through a collection vessel that removes any residual solvent. This moves the solvent back into the tank, which is referred to as a “closed-loop” system. This is repeated until no hydrocarbon solvent remains. Lastly, there is a final purge that uses a variety of methods depending on the desired end product. Because hydrocarbon cannabis extraction equipment is typically less expensive than ethanol or CO2 equipment, it can be a good option for start-up operations and businesses interested in making small batches.

Solventless Extraction

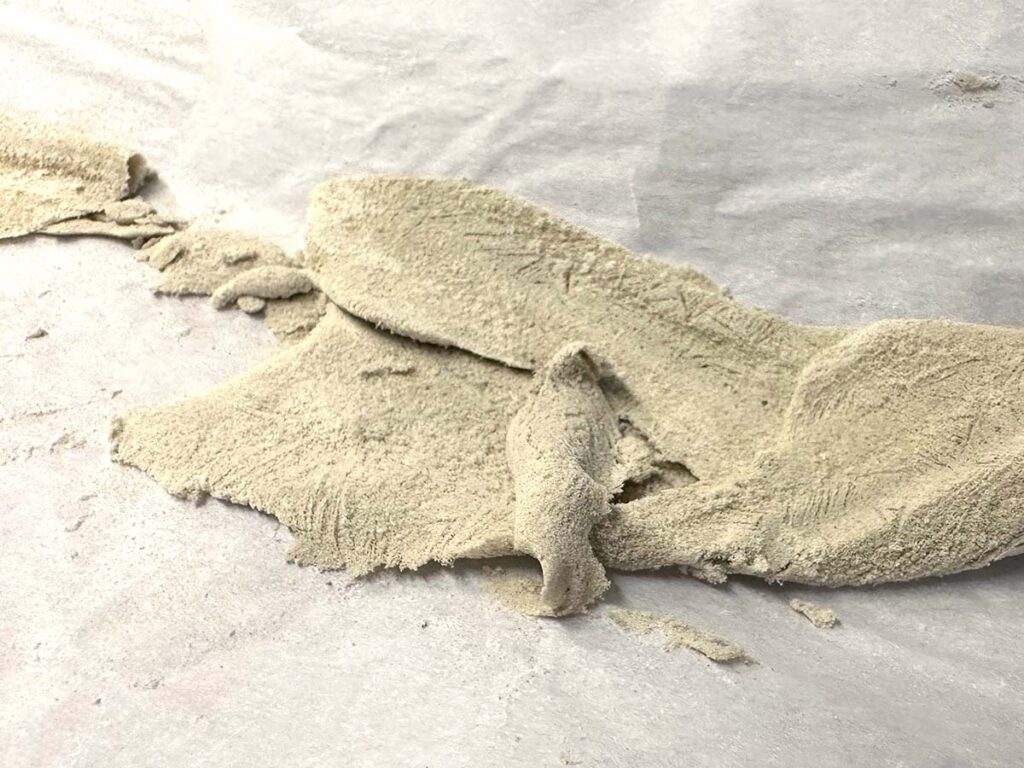

Solventless extraction equipment extracts trichomes from the plant without using any solvents. Solventless extraction can be done using ice water and agitation, an extraction process that produces high-quality ice water hash (bubble hash). Solventless extraction can also be performed using heat and pressure to create rosin.

How To Choose The Best Equipment For Your Business Needs

When choosing cannabis extraction equipment, there are a few key things to think about before making a final decision.

Make Sure The Equipment Meets Industry Standards

Regulations in the cannabis industry are constantly changing, and it’s vital to ensure the equipment is certified and compliant with the highest industry standards. Good Manufacturing Practices (GMPs), for example, are standards upheld by the Federal Food, Drug, and Cosmetic Act (FDCA) that guarantees products are created safely and consistently in a particular facility. GMP is widely considered the gold standard in the cannabis industry for quality and purity. And while regulations for cannabis vary between states, the best producers will operate in GMP-compliant facilities. It’s also important to make sure cannabis extraction equipment meets the requirements of your state. Ensuring you’re aware of state regulations and any necessary licensing conditions is imperative before choosing the best extraction system for your location.

Consider The Facility Where Extraction Will Take Place

Whether designing and building your own extraction lab or working in an established location, the facility that will house your extraction equipment is also important to consider before making your final decision. Plumbing, electricity, and exhaust systems are all things to consider. The facility you use and licensing you need will also largely depend on state laws and the type of extracts you plan to produce. For example, laws are typically stricter for butane extraction than they are for solventless and other types of extraction.

Keep Your Business Budget In Mind

Keeping your business budget in mind is key to your continued success. It’s important to take a solid look at your business plan and your long-term business goals before this kind of investment. How much can you afford to invest upfront? What is your expected growth? Can the equipment be scaled for future growth? How can you maximize the return on investment (ROI) of extraction equipment while adhering to your business budget?

Implementing Extraction Equipment Into Your Business

Once you’ve chosen the best extraction system for your business comes the exciting part of implementing the equipment into your business so you can create high-quality cannabis extracts. The following are a few things to keep in mind as you learn how to use your new cannabis extraction equipment.

Understand Each Part Of Your Equipment

Depending on what type of equipment you choose, there could be several different parts contained in the machinery itself. Understanding every aspect of your extraction equipment is key to using it properly. Familiarize yourself with connectors, supply tanks, tubes, filters, and whatever else your equipment contains.

Determine If Training Is Necessary For You Or Your Team

Do you and your team have extraction experience, or are you new to the extraction process? Are you expanding your extraction business and need to know how to process cannabis extractions on a larger scale? Knowing what type of training you’ll need (if any) is vital before you begin.

What Type Of Cleaning And Maintenance Is Needed

Cleaning and properly maintaining extraction equipment is crucial. The equipment manufacturer should provide what’s needed, including any regulations or essential tools necessary to clean your commercial cannabis equipment. You should also plan to develop a cleaning schedule and log when the equipment has been cleaned and sanitized.

Build A Backup Supply of Parts That Typically Need Replacement

All mechanical equipment contains parts that sometimes need to be replaced. To ensure consistent productivity, building a backup of parts that generally need to be replaced is beneficial. From small screws and filters to different belts and assembly components, having a supply of replacement parts is a smart way to keep your business running smoothly.

How Mobius Equipment Can Help With The Extraction Process

Whatever extraction equipment you end up purchasing for your cannabis business, Mobius can help you meet your extraction needs. With mills designed specifically to grind cannabis for pre-rolls and extracts, Mobius’ commercial grinders offer a consistent grind, with particle size options for every type of cannabis application, including extraction production.

The M210 Cannabis Mill, for example, is equipped with screen configurations that optimize CO2, ethanol, and hydrocarbon extraction processes. Grinding to the optimal particle size based on a specific extraction method can deliver higher extraction yields and fewer inefficiencies. Ultimately, increased efficiency in grinding cannabis material before the extraction process leads to increased extraction effectiveness.

We invite you to contact us today to learn more about how Mobius Mills can help your operation run more efficiently or improve your current extraction process. With consistent particle sizes and no heat degradation to plant material, our commercial cannabis grinders are designed to produce high-quality cannabis extracts.

We’re also here to offer any support we can in helping you determine the best cannabis extraction equipment depending on what extracts you’re interested in for your personal business needs.