Advanced Wash System with Integrated Cooling

M100 Solventless Wash System

200 Gal. Pre-Chill Reservoir

High-volume Washing

15-60 Lbs/batch

Automatic Wash Sequences

Dewatering Technology

Commercial-Scale Operation

Supercharge your bubble hash extraction with an integrated, multi-vessel system for efficient and seamless hash production.

Smart Automation

Integrated sensors auto-detect water levels and temperature throughout the system and maintain optimal washing conditions. Set and save recipes to run automatic wash sequences from the user-friendly touchscreen interface to create repeatable processes in your lab.

5x Faster Hash Collection

The free-rolling collection module houses the dewatering system and collection vessels, allowing for efficient and streamlined hash collection. Add-on extra collection modules to create a continuous workflow by exchanging modules during the collection process for non-stop production.

Unified Multi-Vessel System

The Mobius M100 Wash System features multiple vessels connected through an internal cooling circuit. The system allows hash experts a streamlined workflow with a 200-gallon cooling reservoir, a 100-gallon wash vessel, and a 100-gallon water recovery and recirculation vessel.

Operating Capacity

Wash Vessel Volume

Fresh Frozen Input

Dry Flower Input

The Future of Hash Washing

Industry-leading features bring the M100 Washer to the forefront of commercial hash extraction.

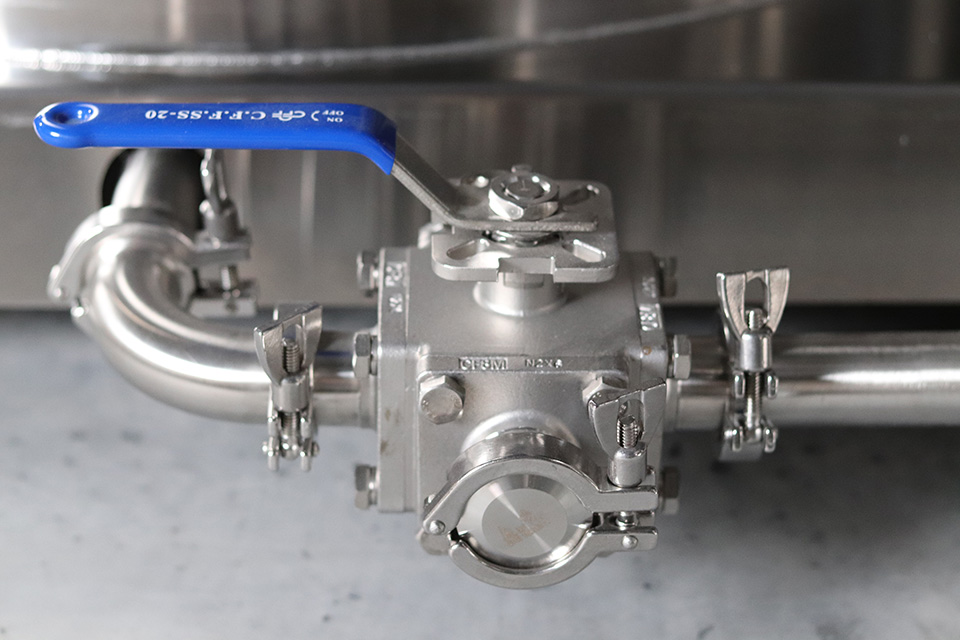

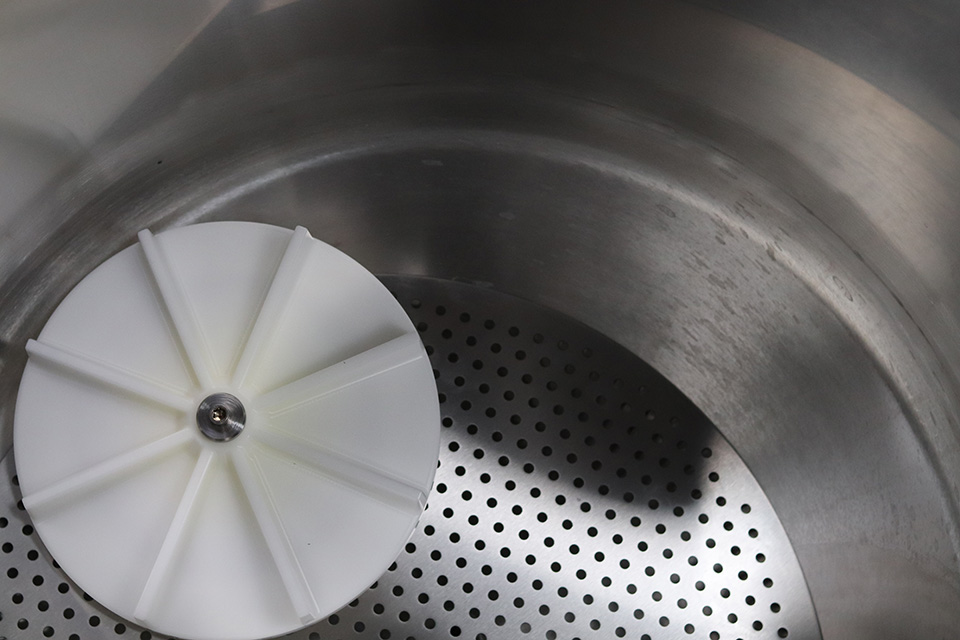

Dewatering System

Advanced centrifugal design protects your trichomes during dewatering without using destructive vibratory force, speeding up your trichome filtering and collection process. Achieve a streamlined hash collection process that’s 5x faster than manual filtering.

Integrated Cooling

The cooling reservoir pre-chills 200 gallons of filtered, water at approximately 32-34°F, the optimal temperature for hash washing. Connect the washer to a chiller and the internal glycol jackets will actively cool the vessels throughout all stages of the wash, eliminating the need for ice.

Reduce Costs

100-gallon water recovery and recirculation vessel allows you to reuse the water from each wash cycle to the next. Reduce downtime and minimize operating costs associated with cooling, filling, and emptying your wash vessels.

Vortex Technology

Our proprietary off-set design creates a continuous rolling vortex, allowing for gentle and easy trichome separation for unrivaled washing efficiency.

Industrial-Grade Collection Bags

Complete your bubble hash collection process with the Mobius x Boldtbags professional-grade filtration bags. The Lock-Top bags seamlessly integrate with the M100 collection vessel to optimize your solventless extraction workflow, while helping you save money and processing time with every wash cycle.

Customized for Your Facility

Get individualized support from our team to get you set up with your M100 Wash System. We’ll come to your facility to help train and onboard your staff and provide continued assistance. Connect with an expert to learn how we can provide a unique solution for your solventless extraction lab.

Get the M100 Solventless Wash System

Resources

Integrate with the Automation Suite

FAQs

How much hash can I wash in a day?

The number of washes per day will depend on your flower preparation and operation capacity. With the free-rolling collection module and integrated cooling, producers can run continuous wash cycles without having to stop for collection or to chill the water. Add on extra modules for non-stop collection capabilities.