Best Pre Roll Machines for High-Volume Cannabis Cultivators

With the pre roll industry booming, cannabis businesses can benefit from commercial pre-roll machines. The growth of pre roll sales in the cannabis industry has wildly outpaced other product categories; with year-over-year growth approaching 50% in key markets, marijuana pre-roll production presents an exciting opportunity for cultivators of all sizes.

Pre-rolls win producers a healthy profit because of their high price per gram, but high labor costs eat into the returns. This cost dynamic has led forward-looking producers to invest in pre roll automation equipment that speeds production and meets demand at far lower operating costs. If you want pre-rolls to be a breadwinner, hand tools aren’t going to cut it. Tools such as an automated pre roll machine may be the answer by making pre-rolls more profitable.

However, not all pre-roll machines have the same features, throughput, build quality, or staffing requirements, so it is crucial to educate yourself before purchasing.

This article explores commercial pre-roll machines currently available and describes a few of the most popular models.

How to Find the Best Commercial Pre-Roll Machine

Selecting a pre roll machine may seem simple at first. Cannabis companies might expect that comparing joint rolling speed, production capacity, and warranties of various pre-roll machines will suffice. Then, factoring in price and reputation, they can make their purchase.

However, a pre-roll machine’s varying usage dynamics will complicate the decision, so you need to understand your needs from a rolling machine before proceeding.

Labor and workflows vary from one pre-roll machine to another. For example, a pre-roll machine may claim high instantaneous speeds (e.g. 300 pre-rolls in two minutes or 100 pre-rolls in 60 seconds) but require extensive labor before and after the operation cycle. Though the actual run time is brief, other tasks — such as loading the cones into the machine or twisting the pre rolled cones closed — may require hours of work.

Speed is important, but a better metric for efficiency is the number of employees the machine can offset, and how you envision it fitting into your workflow.

Types of Pre-Roll Machines

Volumetric

Volumetric pre-roll machines measure the contents of the pre-roll cones by approximate volume (rather than weight). And though they may boast speeds equivalent to a larger filling machine system, they provide less automation.

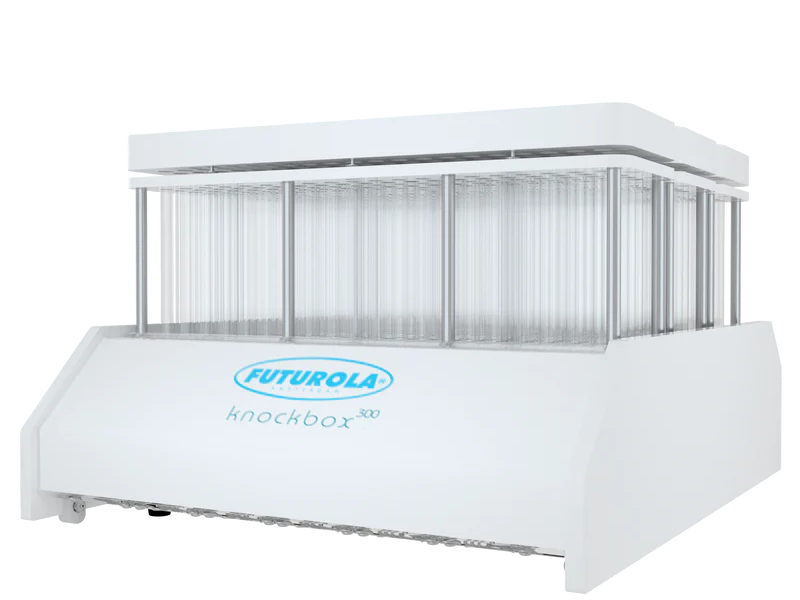

Most volumetric machines, such as the Futurola Knockbox, use motorized vibration to fill upright cones with ground cannabis. The number of cones varies depending on the cone loader tray, as do the compatible cone types and sizes.

Though volumetric machines save labor, they cannot be considered “commercial pre-roll machines” when compared to more automated alternatives. Operators still need to load the cone filling machine and twist the cones closed after the machine runs.

A volumetric filling machine is a useful, affordable tool for smaller, well-staffed operators who need to roll hundreds of cones per day but are not workable for operations that need thousands.

Commercial

Commercial pre-roll machines vary in design, but all are significantly more complex than desktop units. Deeper automation requires more contact points with the cone and cannabis, more mechanized actions, more moving parts, and more floor space.

However, commercial joint rolling machines dramatically reduce labor because they eliminate the tasks of loading the cones, tamping them, and twisting them closed.

Most of these machines measure the marijuana by weight rather than approximating weight by volume. You should also consider the capital lost when over-filling joints due to this process, compared to a more precise system. Weight-based dispensing is more accurate and better for jurisdictions with tight tolerances.

Larger machines may also increase product quality by making the pre-rolled cone more evenly packed. Some machines forego the cones and roll the pre-roll closed rather than fill it from the top — a method that purportedly gives you that perfect cone and increases the burn quality (and reduces the cost of goods sold).

Important Things to Consider

Choose Your Cone First

Not all machines accommodate all pre-rolled cone sizes. So, if you have specific intentions for your pre-roll line, check for availability of cone sizes and to see if your machine will do the job before further consideration.

The most popular cone materials are organic paper, hemp, rice, and flax. The most common sizes — which the majority of machines will accept — are 84mm, 98mm, and 109mm.

Check for Burn Qualities

Speed is the obvious selling point of commercial pre-roll machines. Yet the quality of the machine’s final product — the pre-roll itself — is every bit as important.

Well-packed pre-rolls burn evenly and deliver good “burn quality.” This is a critical factor for a premium smoking experience.

Unevenly packed pre rolls produce “runners” or “canoes” as they burn, with the paper burning more quickly on one side than the other. They may also extinguish while smoking due to loosely packed spots, or break during transit.

A good pre roll creates an oil ring of cannabinoids and terpenes around the burning end of a lit joint. The smooth progression of heat through the plant material lets cannabinoids vaporize at lower temperatures as the cherry moves toward the filter tip.

The main factors affecting the packing density of the pre roll are the grind size, grind consistency, compaction, and the resinous quality of the material — along with the capability of the machine itself.

To assess the packing capabilities of a pre-roll machine, look for consistent material density throughout the cone, and beware of loosely packed areas near the filter tip. And make sure to sample the product to experience the burn quality firsthand.

How Much Does a Pre-Roll Machine Cost?

Volumetric pre roll machines range from 3,000 to 18,000 USD, depending on the model and cone capacity.

Commercial pre roll machines, which often feature touchscreen interfaces and custom tooling, may cost 100,000 USD or more.

The price difference is quickly offset by labor reductions, yet low-volume producers should consider other high-ROI equipment, such as trimmers, buckers, or conveyors. These processing systems set the stage for successful and consistent pre-roll automation later and may result in a higher ROI.

Also, budget for a cannabis mill, and be aware that your choice of a mill will affect the quality of your final cannabis products. The best cannabis mills — such as the Mobius M210 Cannabis Mill and M60 Compact Mill — operate at low temperatures and utilize precise milling surfaces for a superior final product. Click the above links for more information on the Mobius Mills.

Which Pre-Roll Machine is Best for You?

Your production volume will largely determine your degree of automation. The larger the production volume, the quicker a commercial pre-roll machine pays off.

However, all producers have varying requirements, product intentions, and ordinances. Here are a few machines representative of current market offerings:

For Larger Producers and Wholesalers: AutoCone System+

Like most commercial machines, technicians add ground flower into a hopper. Then, the machine weighs the ground flower, fills the cones, tamps the flower, and twists or cuts the tops.

Users of the AutoCone report that the machine can process various strains of flower that may cause problems in other machines. The AutoCone machine also has additional optional parts to accommodate a wide range of cone sizes.

The AutoCone System+ from Plan Automation LP Inc. operates at 30+ joints/minute, depending on strain type and fill amount, and features an integrated machine web camera for service support and remote access for troubleshooting.

For Multi-Location Retailers: RollPros Blackbird

The Blackbird from RollPros rolls joints from a ream of rolling paper rather than using cones. The benefit of using rolling papers this way includes a more even distribution of the ground flower than is possible with vertical tamping, which creates a better smoking experience for marijuana consumers.

The process starts with adding ground flower to the machine to be weighed and distributed, then rolled into joints. Because the Blackbird rolls rather than tamps, it can handle pollen-infused flower that is too sticky for some other machines.

A single person can operate the machine, producing 750 pre rolls per hour while maintaining a +/-0.03g accuracy. The company estimates that foregoing the pre roll cone reduces the cost of goods sold to 0.03 USD per pre-roll (excluding the cannabis itself).

For Boutique Dispensaries: Futurola 300

The Futurola 300 will suffice for producers who are not ready to invest in greater automation. This high-volume knockbox fills 300 cones in 90 seconds, but the actual speed will likely be much lower than the cycle time.

Compared to the fully automated machines above, the Futurola requires more attentive labor and yields less accuracy. Technicians must manually close each cone before packaging — a task that, even with two or three employees — cannot be accomplished at a rate of 300 cones per 90-second interval.

Further, the machine does not weigh the cones. It estimates weight based on fill volume. This strategy requires technicians to randomly test the weight of the pre rolls to meet regulations. In markets with strict variance requirements, volumetric weighing may pose problems.

Yet for smaller producers, the Futurola 300 can expedite manufacturing, reduce labor, and easily meet the sales volume of multiple retail locations — all at a far lower price point than fully automated alternatives.

| Model | Speed | Type | Measurement | Price |

|---|

| AutoCone System+ | 1,800+ / hr | Cones | By weight | $$$ |

| RollPros Blackbird | 750+ / hr | Roller | By weight | $$$ |

| Custom Cones USA | 800-1,500 / hr | Cones | By weight | $$$ |

| Futurola 300 | 300 / 90 sec cycle* | Cones | Volumetric | $ |

*refers to instantaneous speed, not representative of real-world operation

The Best Cannabis Grinders and Trimmers for High-Quality Pre-Rolls

A commercial pre-roll machine is only as good as its accompanying grinder. A good industrial cannabis grinder — more accurately called a mill — will maintain a consistent grind and particle size for an even burn while preserving cannabinoids for quality.

In the marijuana industry, the best-built mills utilize sharp cutting surfaces, like rasps or blades that cut — rather than “grind” or “whip” — the material. This preserves the cannabinoid-rich trichomes that are otherwise prone to damage. A good grinder also keeps the material cool to avoid the evaporation of cannabinoids and delicate terpenes.

Be aware that your choice of trimmer will also affect the results you achieve with a commercial pre-roll machine. The best cannabis trimmers handle the product gently to protect potency.

And some trimmers — like the Mobius M108S — feature trim collection systems specially designed to preserve trim quality for cannabis oil extraction and pre-roll usage. Because the M108S vacuums the trim from the cutting tumbler without exposing it to fan blades, the trichome count and potency is better-preserved. Click the above link to learn more about the Mobius M108S trimmer.

Get Ready to Roll

Mobius offers high-speed equipment that complements commercial pre roll production, such as the M108S Trimmer (capable of up to 120 lbs/hr | 55 kg/hr, wet) and the M210 Cannabis Mill (up to 200 lbs/hr | 90 kg/hr, dry).

If you’re ready to operate at a commercial scale, consider an on-site demo of cannabis processing equipment at our Mobius facility in Las Vegas, Nevada. Qualified prospects will receive airfare and lodging stipends, as well as free airport pickup.

Learn more about the Mobius VIP Experience here and how Mobius processing equipment can help increase the gains from commercial pre-roll machines.