How to Assess Cannabis Harvesting Equipment: Purchase Criteria for Getting the Most Out of Your Harvest

Learn how to find the best cannabis harvesting equipment. Bud trimmers, buckers, sorting machines, and more help you process your harvest quicker while maintaining quality.

Cannabis harvesting equipment has evolved as quickly as the cannabis industry, becoming faster, more reliable, and easier to use throughout the harvesting process.

Much as before, automated equipment reduces operating expenses and shortens the period between harvest time and sale. Yet now, it also improves quality metrics related to separating (“bucking”) flowers from the stems, trimming the flowers, and sorting flowers by size for optimal marketing.

If you are considering a cannabis trimmer, cannabis bucker, conveyor, or sorter, due diligence will pay dividends. Understanding the three classes of cannabis and hemp harvesting equipment will greatly benefit your business.

After reading this post, you will be better able to assess the quality and operation dynamics of cannabis harvesting equipment and make informed purchases.

The Three Classes of Cannabis Harvesting Equipment

The previous decade has observed three stages of cannabis harvesting automation, and equipment that has evolved in a logical sequence.

- Manual processing | No specialized equipment (scissors)

- Semi-automation | First-generation equipment

- Integrated Automation | Industrial-grade equipment

Trimming Scissors/Manual Processing

Processing by hand is a technique from a bygone era. Previously, the manufacturing of mechanical cannabis trimmers was not feasible, so large-scale cultivators and growers were forced to rely on large, seasonal trim crews.

Employing dozens of people to trim cannabis with trimming scissors brought myriad problems: high payroll, constant staffing issues, and increased risks of theft, microbial contamination, and legal exposure.

Today, manual processing remains common but impractical at scale. Though the possibility of arrest is gone, harvest-related payroll drives up operating expenses and makes cultivators less competitive with firms that have automated their harvesting process.

If you’re a late adopter of automated processing equipment, you continue to experience high payroll expenses. You expose your marijuana and hemp harvest to outside contaminants from overhandling, which may cause quality to suffer from the inconsistencies of employee-to-employee variances in standards and attentiveness.

Undue risk of employee theft remains a concern for cultivators and growers who process manually. Furthermore, manual processing inhibits company growth due to workspace restrictions, staff scheduling difficulties, and the inability to handle high-volume harvests.

First-Generation Equipment

Early in the legal-cannabis era, many companies developed equipment that solved production problems such as cannabis trimming, cannabis bucking, etc.

Until then, no one had devised a way to mechanically trim cannabis at scale, nor had anyone developed outdoor harvesters, buckers, cannabis-optimized mills, or other equipment we now take for granted.

These first iterations of equipment solved problems for the first time, and the results were revolutionary. Harvest times dropped, product quality remained acceptable, and cultivators were pleased with the lower processing costs.

Yet the first generation of cannabis harvesting equipment — while revolutionary — did not meet the standards of established industries. Consumer-packaged goods companies would have balked at the build quality and operability of these first machines.

For first-generation equipment engineers, operability was an afterthought — as was the equipment’s service life. Their early efforts focused on achieving a harvest quality similar to that of hand trimming.

Most equipment on the market today can be classified as “first-generation.”

These machines need frequent cleaning and frequent maintenance, yet are difficult to disassemble. Operators often neglect these tasks and suffer suboptimal product quality. And, even in instances of proper maintenance, these machines have a short service life.

Industrial-Grade Cannabis Processing Equipment

According to Research And Markets, the global cannabis market reached USD 25 billion in 2021 and will grow to USD 176 billion by 2030. As such, there is a paradigm for cannabis cultivation, and a new breed of cannabis and hemp processing equipment is beginning to emerge.

Today, leading cultivators and growers leverage economies of scale in all aspects of their operation, from fertigation to packaging. Like other industries, they reduce costs by making processes and equipment more efficient and automatic. And they improve product quality control through mechanization and standardization of procedures.

Characteristics of Industrial-Grade Cannabis Equipment

- Created by industrial manufacturers with established track records and innovative technologies

- Designed for compliance with Good Manufacturing Practices (GMP)

- Ability to integrate with other equipment systems

- Lower maintenance and enhanced cleanability

- Easy operation and automatic adjustments

- Longer service life

This new grade of cannabis processing equipment solves the maintenance and operability problems created by the first with many distinct advantages. It brings cannabis cultivators in line with other industries and delivers the performance a pharmaceutical operations manager would expect from processing equipment: ease of operation, low maintenance, short downtimes, reliability, and speed — as well as great performance.

Equipment Buying Criteria

Your cannabis processing equipment must deliver a high-quality final product with well-preserved potency and optimal aesthetics. Beyond that baseline requirement, several criteria apply.

Quality

Savvy consumers can discern a quality product based on its sturdy construction, high-end materials, and well-machined joints and surfaces.

But you should also look for warranties and a well-established customer support program. Quality manufacturers back their equipment with warranties. Less-capable manufacturers find warranties cost-prohibitive.

GMP-Readiness

Good Manufacturing Practices (GMP) are a set of standards that protect consumer safety in the food and drug industries.

Choosing GMP-ready equipment assures quality as well as compliance because these machines are built to a higher, more hygienic standard. They have durable, cleanable surfaces, and employ lubricants and materials that are all food-grade.

In the United States, industry pundits expect GMP standards to apply universally when cannabis is federally legalized. The US Food & Drug Administration will likely view cannabis as a food/drug product and so apply GMP standards accordingly. Choosing GMP-ready equipment today will protect your compliance into the future.

Operability and Maintenance

Equipment should be easy to operate with features for automatic adjustment and calibrations. If your operators struggle to learn or use the equipment well, their productivity will suffer.

Assess the cleaning and maintenance intervals of your potential new machine. Cannabis pollen adheres to warm surfaces very easily, so trimmers naturally need multiple cleanings per shift. If the cleaning process is difficult and the machine requires recalibration upon assembly, deduct that time from your anticipated processing speed.

Scalability & Integrability

A hallmark of industrial-grade equipment is integrability — the ability to integrate with other equipment systems or expand functionality in the future.

Integrability makes scaling your business and commercial operation simple. When you need to increase your harvesting capacity, you can add machines that compliment your current setup rather than present compatibility issues. When you need to relocate indoor equipment to an outdoor facility, you can do that too. Integrating conveyors, for example, will streamline your production process, seamlessly carrying cannabis material from one stage to the next.

Types of Cannabis Harvesting Equipment

Automation technologies extend from when the plants come down until the retail package is sealed.

Cannabis Trimmers

A Mobius trimmer, such as the Mobius M108S, will be the nexus of your processing system. The purchase criteria for trimmers should include:

- Automatic blade adjustments (no manual adjustments after cleaning/disassembly)

- Variable controls for wet and dry trimming

- GMP readiness and scalability

- Easy cleanability and simplified maintenance

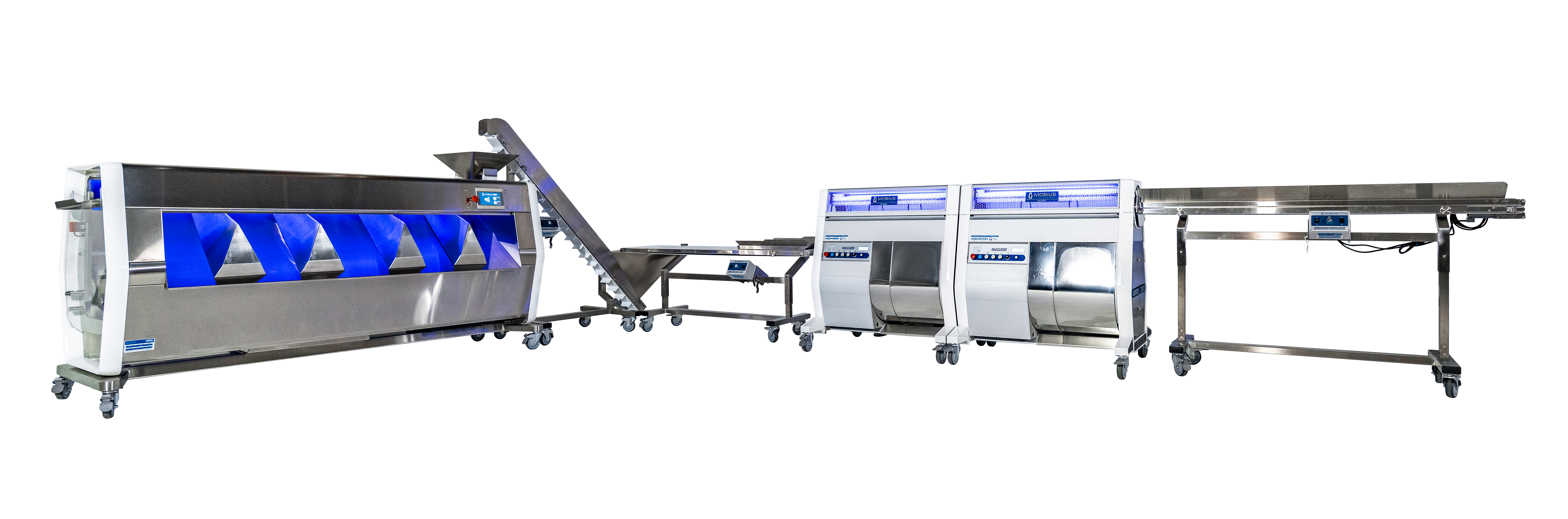

The Mobius M108S checks all the boxes with a knife system that never requires adjustment, easy disassembly, and total adjustability of tumbler speed, vacuum speed, and blade speed. When you are ready to scale your cannabis production, the Mobius can run another trimmer in tandem for greater speed. Learn more about the Mobius M108S.

Cannabis Buckers

A bucker quickly separates flowers from the stems of the cannabis plant in preparation for dry or wet trimming. Without a high-speed cannabis bucker, your trim crew will struggle to meet the speed of an industrial-grade trimmer. The best buckers feature:

- Variable speed settings for wet and dry, delicate material

- On-board stem processing for easy disposal

- GMP readiness

The Mobius MBX Bucker includes all of the above in a rugged 304 stainless steel construction with an optional off-road wheel system for outdoor grows. Learn more about the Mobius MBX Bucker.

Cannabis Conveyors

The Mobius Conveyor systems create a streamlined throughput of flower material during each phase of the post-harvest process. The conveyors can be combined with the M108S Trimmer and M9 Sorter to keep your cannabis consistently moving to the next step with no manual labor. For the best results, look for these qualities in conveyor systems:

- Feed consistency with adjustable speeds and reversible belts

- Easy installation and disassembly for cleaning

- GMP readiness

Mobius offers infeed & outfeed systems as well as an Autofeed Conveyor for maximum automation. Learn more about the Mobius Infeed & Outfeed Conveyors.

Cannabis Sorters

The Mobius M9 Sorter divides flowers by size for optimal marketability. The large flowers achieve their full price potential, while smaller flowers can be used for pre-rolls and cannabis extract. Apply these criteria to your purchase decision:

- Speeds that match or exceed the trimmer

- Easy adjustability and disassembly for cleaning

- GMP readiness

The M9 features nine sorting belts for industry-leading speed and tool-free adjustability and fast disassembly for cleaning. Learn more about the Mobius M9 Sorter.

Customer Service Starts Now

A responsive service team that quickly answers questions is critical to your success, so at Mobius, we take service as seriously right from the start.

For qualified prospects, we offer in-person demos via our expenses-paid VIP experience in sunny Las Vegas, Nevada. The Mobius VIP Experience includes stipends for lodging, airfare, and complimentary airport pickup.

Please submit your inquiry here to learn more about cannabis harvesting equipment and see if you qualify for the Mobius VIP Experience.