How to Calculate ROI for Process Automation

Process automation is a serious investment, and the best-run facilities treat it like one. This guide explains how to calculate return on investment (ROI) for automation projects with clarity and confidence. You’ll learn which metrics matter, how to approach both hard and soft benefits, and what factors influence ROI timelines.

At Mobius, we work with some of the largest commercial cultivators and specialty processors in North America. Our experience designing automation solutions gives us deep insight into how capital investments pay off and what it takes to make them work.

What Is Process Automation ROI?

Return on investment, or ROI, is the key metric that helps determine whether an automation project makes financial sense. At its core, process automation ROI compares the cost of implementing automation technology to the tangible and intangible value it creates over time. The basic formula is simple:

ROI = (Net Return ÷ Investment Cost) × 100

But in practice, calculating ROI requires a broader view, especially when automation influences both operating costs and long-term scalability.

Hard vs. Soft Returns

The most immediate return comes from hard cost savings. These are quantifiable benefits such as reduced labor expenses, faster throughput, fewer errors, and lower waste. For example, replacing manual sorting or trimming with automated systems can substantially reduce the time spent per unit processed, which translates directly into labor cost reductions and increased output.

However, ROI also includes soft returns that are harder to quantify but often are just as valuable. These include improvements in product consistency, process visibility, employee satisfaction, and overall responsiveness to changes in demand. In industries where compliance, standard operating procedures, and brand reputation are critical, these softer benefits help to further justify automation efforts.

Why ROI Matters to Decision Makers

Beyond measurement, ROI plays a central role in gaining leadership approval. Executives and financial decision-makers rarely green-light large capital investments without a clear understanding of both cost savings and revenue potential. A well-supported ROI case gives stakeholders the confidence that an automation initiative will not only reduce expenses but also create a pathway for growth by unlocking greater production capacity, improving time-to-market, or expanding product lines.

In fact, the most successful process automation strategies are those that position ROI as a business-wide value driver. It’s not just about doing the same work faster or cheaper; it’s about building a more resilient, efficient, and scalable operation that supports long-term goals.

Industry Data on Automation Success

Across industries, automation has proven to deliver measurable returns. According to a 2023 report from the Harvard Business Review, 91% of organizations agree that automation helps improve business performance, with major gains reported in both revenue and operational efficiency. Deloitte’s 2022 survey on intelligent automation showed that 92% of companies achieved positive ROI, with the most successful organizations reporting cost reductions and improved compliance within the first 12 months.

In the food, agriculture, and public sectors, a McKinsey study points out the potential for productivity improvements ranging from 15% to 40% when an automation initiative is combined with reskilling and organizational change. Additionally, a recent review in Technological Forecasting and Social Change found that businesses that strategically adopt automation technologies experience a 20% increase in process efficiency, particularly when integrated into existing digital infrastructure. These results underscore that automation when implemented strategically, is more than a cost-saving tool; it is a catalyst for scalable, long-term growth.

What Are the Hard and Soft Benefits of Process Automation?

Quantifiable Gains: Hard Benefits

The most immediate and measurable impact of workflow automation comes from its hard benefits. These are direct financial gains that can be tracked in your operational data. Labor savings are often the headline metric, especially in facilities where manual tasks like sorting, trimming, packaging, or inspection dominate the workflow. By automating these repetitive tasks, producers can reduce headcount or reallocate labor to higher-value responsibilities.

Other hard benefits include improved cycle times, reduced scrap and rework, lower cost per unit, and higher overall throughput. In regulated sectors, automation supports GMP compliance and reduces the likelihood of violations, which can result in considerable financial penalties. For example, replacing manual batch tracking with integrated automation and data logging reduces both human error and the risk of missing documentation, which is a critical advantage for cannabis processors and food manufacturers alike.

Transformational Advantages: Soft Benefits

While harder to quantify, soft benefits are often what tip the scales in favor of automation. These include operational improvements that support broader business transformation: increased process consistency, better visibility across the production line, and improved agility in response to shifts in demand or product mix.

Employee satisfaction also tends to improve when monotonous or physically taxing tasks are automated. Workers can be retrained for supervisory, maintenance, or quality control roles, increasing morale, and reducing turnover. In environments where safety is a concern, such as handling sharp tools, hot equipment, or biohazardous materials, workflow automation also plays a key role in reducing risk.

Customer experience is another critical but indirect gain. Automation supports standardized outputs and repeatable quality, which translates to fewer defects, faster fulfillment, and higher brand trust. It also supports traceability, which is increasingly demanded by both regulators and consumers in sectors like food, supplements, and cannabis.

Enabling SOPs and Long-Term Process Control

Another often overlooked benefit is the ability to formalize and scale standard operating procedures. Automated systems follow the same logic every time, which makes it far easier to define, monitor, and refine SOPs. For producers managing multiple facilities, or those that are planning to scale, this kind of repeatability is foundational. It enables consistency across batches, locations, and even product lines, making it easier to meet compliance standards and expand operations without sacrificing quality.

How to Calculate ROI for Process Automation

Step-by-Step Approach to ROI Calculations

Calculating ROI for process automation begins with identifying both the investment costs and the measurable returns. The investment side typically includes one-time and recurring costs such as equipment, software licenses, integration, system design, facility modifications, and training. Depending on the size and complexity of the industrial automation project, these figures can vary significantly across industries, but the structure of the calculation remains the same.

The standard formula is:

ROI = (Net Return ÷ Investment Cost) × 100

To use this formula effectively, you’ll need to account for all relevant cost inputs and performance outcomes. This means capturing data like reduced labor hours, lower waste or scrap percentages, and improved throughput or yield. For example, an operation that invests $100,000 in a conveyance and trimming system and sees $60,000 in annual labor savings, plus $10,000 in reduced product loss, would calculate net return as $70,000. This results in an ROI of 70% over a one-year period.

Cost Categories to Include

A robust ROI calculation considers more than just hardware:

- Hardware & Equipment – The purchase price of machinery, conveyors, sensors, or trimmers.

- Software – Automation control systems, monitoring dashboards, and integration with ERP or MES platforms.

- Implementation – Engineering, installation, calibration, and integration labor.

- Training & Change Management – The time and resources needed to onboard staff and adapt existing processes.

On the return side, measurable benefits might include:

- Labor Efficiency Gains – Fewer operator hours required for the same or greater output.

- Throughput Increases – More units processed per hour or per shift.

- Error and Waste Reduction – Lower rework rates or raw material loss.

- Energy or Utility Savings – Particularly in facilities running high-consumption equipment.

Scenario Modeling: Real-World Automation Examples

Scenario modeling helps decision-makers understand the range of potential outcomes from an automation investment. Businesses can assess risk and plan for contingencies by exploring best-case, worst-case, and most likely projections. Below are example scenarios from cannabis processing, food production, and cosmetics packaging based on average industry estimates.

Cannabis Trimming Automation

A mid-sized commercial cultivator is considering the Mobius M108S trimmer to replace manual hand trimming.

- Investment: $1000,000 (machine, conveyor integration, training)

- Best Case: Labor savings of $70,000 annually by reducing trimming crew from 15 to 4, plus $15,000 in product recovery due to reduced trichome loss = 85% ROI in Year 1

- Worst Case: Initial training delays reduce savings to $4,000, and product recovery is minimal = 40% ROI in Year 1

- Most Likely: Labor savings of $55,000, with moderate product recovery gains = 60% ROI in Year 1

Food Packaging Automation

A dried fruit processor automates weighing, filling, and sealing.

- Investment: $375,000 (equipment, custom PLC programming, staff training)

- Best Case: 50% throughput increase, 25% labor savings, 15% less product loss = Payback in 10 months

- Worst Case: Mechanical integration issues delay full production for 6 months = Payback in 20 months

- Most Likely: 30% throughput gain and 20% labor savings = Payback in 14 months

Cosmetic Product Filling Line

A natural skincare brand upgrades to a semi-automated filling and capping line.

- Investment: $120,000 (compact line, training, facility upgrades)

- Best Case: Fills 4x as many units per shift with half the staff = ROI > 100% in Year 1

- Worst Case: Bottlenecks in labeling and packaging slow the line = ROI < 30%

- Most Likely: Throughput doubles, labor stays stable = ROI of 60–70%

These scenarios help stakeholders visualize what returns look like under different conditions. Even without exact figures, this kind of modeling provides a structured framework for evaluating automation risk and potential.

Tools and Metrics You’ll Need to Measure ROI

Identify Key Operational Metrics

To accurately measure automation ROI, you need a reliable set of baseline metrics: data that reflects current performance before automation begins. Start by tracking how long each task takes, how much labor is involved, and where waste or inefficiencies occur. Useful metrics include:

- Labor hours per batch or per unit

- Yield and scrap rate

- Cycle time per task or production line

- Downtime incidents and duration

- Error rates and rework volume

These figures create a benchmark against which improvements can be measured once automation is in place.

Use Automation Software and Dashboards

Modern automation systems often include built-in analytics or integrate with monitoring tools that display key metrics in real time. Dashboards help operators and managers track performance gains, spot bottlenecks, and validate cost savings as they occur. Some systems also support alerts, predictive maintenance tracking, and data exports for reporting.

Integrating ROI tracking into your automation setup from the beginning ensures that your team can monitor improvements with precision. Whether you’re logging labor reductions, tracking product consistency, or measuring output by shift, the goal is the same: to translate performance gains into clear financial value.

Factors Influencing ROI Timeline

Internal Factors: Training, Readiness, and Culture

Even the best-designed automation system won’t deliver returns without internal alignment. A common delay in achieving ROI comes from underestimating the time and effort needed to train staff and integrate new systems into daily operations. Facilities that invest early in training and change management typically see faster results. Technical readiness also matters: outdated infrastructure, poor network integration, or incompatible legacy systems can all delay implementation and reduce early gains.

Organizational culture plays a role, too. Teams that embrace the automation solution as an opportunity instead of a threat tend to adapt more quickly and use the technology to its full potential. When operators understand the “why” behind automation and see how it improves their work environment, they are more likely to contribute to successful outcomes.

External Factors: Supply Chains, Seasonality, and Regulation

Beyond internal dynamics, external conditions can significantly affect ROI timelines. Supply chain delays, particularly in sourcing specialized components or shipping equipment, can push implementation dates back by weeks or even months. In some industries, seasonality adds pressure. For example, missing a peak harvest or production window can alter expected returns for the entire year.

Regulatory factors also influence how quickly automation begins to pay off. For cannabis processors or food manufacturers, automated systems may need to pass inspection or certification before they can go live. In highly regulated sectors, building in extra time for compliance review is often necessary.

Finally, market demand shapes how quickly automation investments generate revenue. If automation allows a facility to fulfill larger orders, introduce new products, or enter new markets, returns will compound faster. But if market conditions are unstable or demand is flat, even the most efficient system may take longer to reach payback.

How to Strengthen the Business Case for Automation

Use Data-Driven Storytelling

To win stakeholder support for automation projects, you need more than technical specs; you need a persuasive business case. Start with clear ROI projections, backed by real operational data, and present them using visual tools. Charts, dashboards, and scenario modeling make your case more tangible and easier for leadership to evaluate. The more grounded your projections are in current performance metrics, the more credible they’ll be.

Automation initiatives that align with broader business goals are more likely to gain approval. When possible, connect projected outcomes to priorities like scalability, sustainability, or risk reduction. For example, a solution that reduces labor costs while also helping the facility meet regulations like GMP compliance can speak to both operational and strategic concerns.

Include Strategic and Qualitative Value

Beyond cost savings, emphasize how automation supports long-term growth. Can it reduce reliance on volatile labor markets? Will it support consistent product quality across multiple sites? Can it enable faster market entry for new products or SKUs? These are the kinds of benefits that may not appear on a balance sheet, but they resonate with leadership teams focused on agility and expansion.

You should also address perceived risks. Executives may worry about disruption, implementation complexity, or long-term support. Framing automation as a phased strategy, with strong vendor support, clear success metrics, and realistic adoption timelines, helps minimize those concerns.

In short, a strong business case for automation tells a financial story backed by operational data, but it also frames automation as a strategic investment in the company’s future.

Turning ROI Insights Into Action

Calculating ROI is more than just a financial exercise; it’s a strategic tool for building smarter, more resilient operations. By understanding the full range of benefits automation can deliver, from hard savings to long-term agility, operators can make confident, data-driven decisions. Whether you’re working in cannabis processing, food production, cosmetics, or another specialty sector, automation isn’t just about cutting costs. It’s about building the capacity to grow.

If you’re exploring automation for trimming, conveyance, or post-harvest processing, tools like ROI modeling and scenario planning can clarify where to begin. And when you’re ready to take the next step, having the right partners — those who understand your process, your industry, and your goals — can make all the difference.

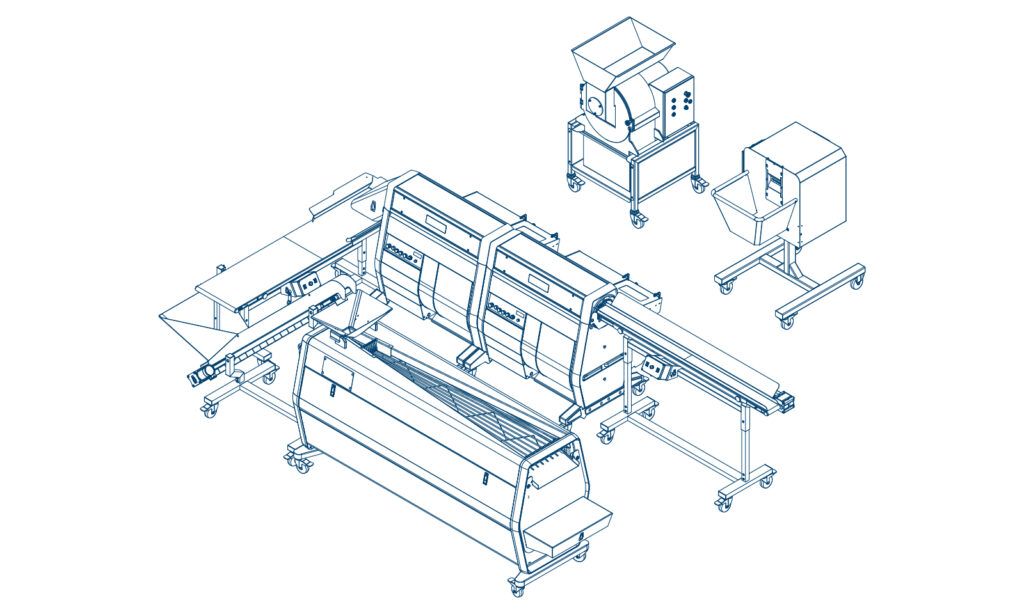

Mobius has helped some of North America’s largest cultivators and processors design automation systems that increase throughput, improve consistency, and reduce labor costs. Our conveyor systems are built for modular integration and engineered to support end-to-end processing efficiency.

Explore our cannabis automation solutions or contact our team to start a conversation about your facility’s goals.