What To Do With Cannabis Trim

If you’re a commercial cannabis grower, you probably know that the quality of your flower is a top priority. One way to increase the profit for your business is to look at how you utilize all parts of the cannabis plant—not just the buds.

Cannabis trim is the excess plant material—such as fan leaves and sugar leaves—that’s removed and trimmed off your buds during post-harvest processing. Utilizing this trim will lead to new avenues of profit. Although trim might be categorized as a “waste product” due to lower quantities of desirable cannabinoids in the plant material, it still has significant value, particularly when the product is “kiefed” before it is used to produce additional products.

Unfortunately, many cultivators overlook the value of trim. Often, effectively gathering and utilizing the leftover product from the trimming process can be time-consuming. Additionally, to create a high-quality cannabis product using trim, other measures must be taken, such as kiefing.

Fortunately, products like the Mobius commercial trimmer have emerged to streamline the process of collecting trim for use in various products. With the right tools, companies can effectively expand their product line with a range of new tinctures, oils, infusions, and solventless rosin products.

Here, we’ll take an in-depth look at the potential of cannabis trim and the most profitable use cases for the product left over by your trimming process.

What is Cannabis Trim?

Cannabis trim consists of the excess plant material that’s obtained during trimming. Primarily, it includes the smaller fan leaves and sugar leaves that are removed during the process. Proper trimming of excess plant material is one of the most important stages in professional cannabis production.

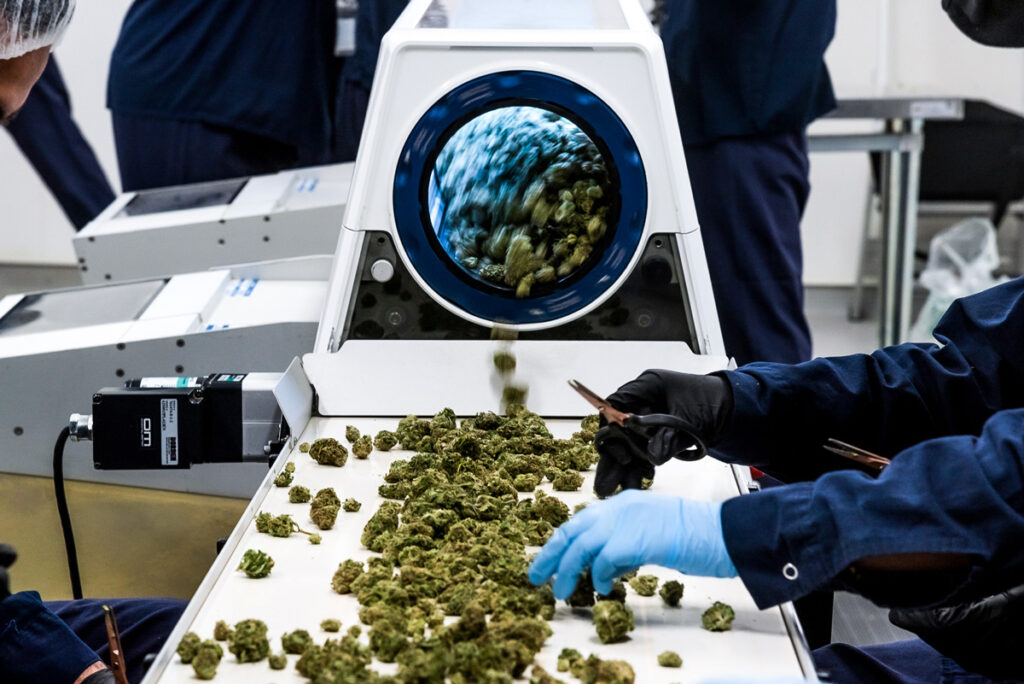

Trimming not only enhances the visual appeal and potency of the final product, but it also improves overall quality. Commercial growers often rely on advanced trimming machines to streamline this process and ensure efficiency.

The Mobius commercial trimmer features industry-leading technology. Designed to handle large quantities of flower, the M108S is ideal for commercial-scale cannabis operations.

Whether you prefer wet trimming or dry, the results rival hand trimming. These innovative machines use precision blades to deliver a close, consistent trim. With their adjustable settings, growers can customize the trimming process to suit their needs and the particular cultivar being processed.

Automated trimming solutions help to minimize the work involved in the trimming process while retaining the quality substances that can be used to create additional products from the trim.

What Makes Good Cannabis Trim?

All leaf foliage removed from the cannabis buds during the trimming process can be considered trim. While some may view this trim as waste, many growers are beginning to recognize its potential and value when it is properly processed to obtain the valuable compounds left over.

Cannabis trimmings can include sugar leaves, fan leaves, small pieces of buds, and any residue left behind, all with their own distinct value. For instance, while big fan leaves may not have much potency, they can have medicinal properties and excellent nutritional value.

Each fan leaf includes a full spectrum of phytonutrients, flavonoids, terpenes, and modest amounts of minor and major cannabinoids. Some consumers even add raw cannabis fan leaves to smoothies and salads. Sugar leaves, on the other hand, are trichome-rich leaves found closer to the buds.

Though they can be harsh on the throat when smoked alone, sugar leaves are excellent for various extraction methods. They are covered in rich trichomes and look like they’re sprinkled with sugar, hence the name. These leaves can contain a decent amount of cannabinoids, which can be added to a range of products.

To transform trim into a valuable product, companies can use the leftover plant material to create kief. Running the trim through a kief tumbler or kief screen can help capture the high-quality trichomes that would otherwise be disposed of in the trim bin of a commercial trimmer. To help with kief collection, processors can use dry ice to facilitate trichome separation.

The Most Profitable Uses for Cannabis Trim

Using cannabis trim effectively requires companies to leverage the right machinery and processes to collect trim without damaging its unique components. After trimming the buds, manufacturers can place the leftover trim into a trimmer with a kief drum to extract the additional cannabinoids and substances from the remaining “waste”.

After collecting kief from the trim and ensuring there are no extraneous materials in the kief (such as stalks and large leaves), producers can use this kief to create a variety of items. For instance, what was once trim can now be used for pre-roll production or extraction purposes.

Methods for Making Extracts

There are various ways to extract compounds from trim, including using solvents or solventless systems. Whether you opt for solvent-based extraction or the increasingly popular solventless and rosin press method, you’ll be able to make the most of your cannabis trim.

As mentioned previously, the first step to utilizing your leftover trim for additional products is to extract the most crucial components from that plant material. Once the kief is isolated from the trim, it can be compacted into a pre-press mold or combined with solvents to create extracts.

Solvent-based extraction involves using solvents like butane, CO2, or ethanol to extract cannabinoids and terpenes from the plant material. This method can be used to make a variety of extracts, including shatter, wax, and vape oils. Solvent-based extraction is more complex and requires specialized equipment and expertise. Additionally, there is a risk of contamination if the solvents are not properly handled.

Solventless methods are becoming increasingly popular among cannabis consumers. Using a rosin press for extraction allows businesses to obtain high-quality extracts without needing solvents. This innovative method involves applying heat and pressure to the material to squeeze out the desired compounds. To make the most of your extraction process, pre-press molds can be utilized to compact the trim, improving efficiency and yielding better results.

In the last two years, rosin has seen a 200% increase in sales, and rosin now makes up approximately 14% of dabbable sales as of 2023.

Make Bubble Hash with Cannabis Trim

After rosin, bubble hash is the second largest solventless dabbable as of 2023, making up around 1% of all sales in January 2023. Bubble hash is a form of cannabis concentrate created using specialist methods to bring out the most potent cannabinoids and terpenes from the plant material.

Hash is currently one of the most popular products on the cannabis market, with overall sales of concentrates increasing by over 40% in 2022. Bubble hash is made by agitating cannabis flower in ice-cold water to separate the resinous trichomes from the remaining plant material. Traditionally, this process is done with whole cannabis buds after they have been bucked, or removed from their stems. Processors can expect a much higher yield following this method, though the process can still be done with the trim left over from trimming.

When using trim to create bubble hash, start by trimming the flowers from your cannabis plants using a high-quality bud trimmer like the Mobius M108S. The trimmed buds can be sold for a premium price while the leftover trim gets a new life. Add the plant material to your washer with cold water and ice and agitate the mixture to facilitate the trichomes separating from the trim. After this process, the mixture is filtered through different micron-sized bags and carefully dried.

Though you can expect lower yields of bubble hash by washing trim instead of whole cannabis buds, you are left with similar results. The end product is a highly concentrated form of cannabis with potent effects and a rich flavor profile.

Edibles and Infused Products

While interest in smoking cannabis products has reduced slightly in recent years, consuming cannabis edibles and vapes has become more popular. In particular, the cannabis-infused edible market is expected to grow to a value of $20.6 billion by 2028.

On a commercial scale, edibles are typically created using whole cannabis buds to deliver the most yield possible. When producing edibles from cannabis trim, the yield will be less, however, you are able to utilize more from your harvest and recapture a profit that would have otherwise been wasted.

The first step to creating edibles using trim is to collect the leftover trim and put it through the kiefing process. While fan leaves can add flavor and nutritional benefits to products, sugar leaves can increase potency and offer extra benefits through unique terpenes.

Once you’ve collected the kief from the trim, you can begin to create edibles. First, you’ll need to activate the cannabinoids through decarboxylation. Decarboxylation is the process of heating cannabis to activate specific compounds.

Then, you can use various infusion methods to incorporate these compounds into different mediums. Common infusion methods include using an oil or butter-based infusion or an alcohol-based tincture.

Added to Joints and Pre-roll Production

Another way to get the most out of your cannabis trim is to use it for certain joint and pre-roll preparations. Pre-rolls have gained tremendous popularity among cannabis consumers in recent years. According to a recent report, pre-rolls make up the second-largest product category in Canada and the third-largest in the U.S. 2022 showed a 54% increase in Canada’s pre-roll sales revenue. To produce pre-rolls, finely grind the cannabis and carefully pack it into the pre-roll cones or rolling papers. Some processors may choose to add the kief from high-quality cannabis trim into their pre-rolls. The use of the kief from trim ensures that the potency and flavor of the pre-rolls are not compromised, while the user enjoys the added flavor and terpene profiles from the addition of the kief.

Quality Control and Testing

Maintaining quality control is crucial when using cannabis trim. For instance, regularly testing your trim for its moisture content, cannabinoid potency, and terpene profiles is essential to ensure consumers receive a safe and consistent product.

Additionally, it is important to check the trim for any contaminants such as mold, mildew, and pesticides. Finally, make sure to store your trim in a cool, dry, and dark place to preserve its quality.

It’s important to implement strong measures to ensure your products meet safety, potency, and regulatory standards. Work with reputable labs to analyze your trim-derived products to ensure consumer confidence. By prioritizing quality control and testing, you’ll establish your brand as a trusted source in the cannabis industry.

Final Thoughts on What to Do with Cannabis Trim

By exploring profitable uses for trim, like creating extracts, edibles, and oils, you can maximize returns while minimizing waste. Embracing the potential of cannabis trim allows you to tap into new markets, expand product offerings, and boost your bottom line.

Invest in high-quality cannabis processing equipment to optimize trim processing and extraction efficiency. At Mobius, we offer the most advanced commercial cannabis trimming machine on the market. Designed for large-scale commercial operations, our trimming machines and processing equipment can help you transform your trim into profit. Contact us today to learn more.