How to Build a Preventive Maintenance Program in 6 Steps

Downtime in high-volume processing facilities can cause businesses to lose thousands of dollars per hour. But the actual cost isn’t just lost time, it includes missed production targets, quality issues, and operational instability. That’s why a strong preventive maintenance program is essential for success.

At Mobius, we’ve worked with large-scale processors across industries, including cannabis, food and beverage, wellness, and specialty agriculture. We’ve seen firsthand how routine maintenance, when treated as a core strategy rather than an afterthought, transforms operations. It reduces breakdowns, extends equipment life, and gives teams the confidence to scale.

In this guide, we’ll walk you through how to build a preventive maintenance plan that works — not just on paper, but in practice. From auditing your assets to training your team and refining your plan, each step is designed for real-world performance and long-term results.

What Is Preventive Maintenance?

Preventive maintenance (PM) is a planned, systematic approach to keeping equipment in top working order. It involves servicing machines at scheduled intervals, whether that’s based on calendar time, usage hours, or performance indicators, to avoid unexpected failures.

This contrasts with reactive maintenance, which only kicks in after something breaks. It also differs from predictive maintenance, which uses live monitoring data to anticipate the ideal time to perform service. Prescriptive maintenance takes it one step further, using AI and machine learning to predict and prevent issues.

Predictive tools are powerful, but planned maintenance forms the baseline; this is especially true in high-stakes processing environments where downtime can compromise both product quality and safety.

For commercial-scale processors, preventive maintenance is the foundation of reliability. It’s how you keep machines running consistently, maintain throughput, and avoid cascading delays throughout your workflow. Over time, it also cuts down on costly repairs and replacements.

Preventive maintenance best practices include:

- Performing routine service to prevent wear and tear

- Replacing components at defined intervals to avoid unexpected failure

- Inspecting systems to catch early signs of mechanical or electrical issues

- Cleaning and maintaining equipment for optimal operation and hygiene

- Adjusting controls and calibrating instrumentation to maintain accuracy

Depending on the process, preventive maintenance may also include specialized tasks tailored to your specific equipment and production environment. These could involve replacing grinding burrs in milling systems, purging solvent lines in closed-loop extraction setups, or verifying airflow and humidity controls in curing and drying rooms. The key is precision — performing the right task at the right time to catch minor issues before they escalate into costly failures.

Step 1: Audit Your Equipment Inventory and Failure History

Before you can manage maintenance effectively, you need a complete and accurate picture of what you’re working with. That starts with a full audit of your equipment: every machine, system, and component that plays a role in production. Think beyond just the high-profile gear. Auxiliary equipment like compressors, conveyors, chillers, and vacuum pumps are often just as critical to smooth operations.

Document everything. A good asset record includes more than just a name or model number. You’ll want to capture the manufacturer, serial number, installation date, maintenance history, known failure points, and usage patterns. Track how many hours the equipment runs per week, what materials it handles, and what conditions it operates under. Dust, temperature swings, and product residues all influence wear rates.

At this stage, even a well-organized spreadsheet can do the job. However, if you already have access to preventive maintenance software, such as a CMMS (computerized maintenance management system), this is where it shows its value. With a CMMS, you can centralize asset data, create maintenance schedules, and track issues over time, all within one system.

Once your equipment inventory is in place, the next step is to dig into failure history. Look at the service records. Identify patterns in unplanned downtime, repeat repairs, or frequently replaced components. If your facility tracks Mean Time Between Failures (MTBF), this is where that metric comes in handy. MTBF helps you prioritize which equipment poses the highest risk to productivity and should therefore receive more frequent regular maintenance.

If detailed logs don’t exist, which in many facilities, they don’t, turn to the people who know the equipment best. Maintenance techs and line operators can often tell you which machines overheat in the summer, which ones clog more often when humidity spikes, and where the weak spots are during longer production runs. Their experience fills in the gaps that data alone might miss.

This audit forms the backbone of your entire preventive maintenance strategy. It tells you what’s in your facility, how those systems have performed in the past, and where the most serious risks lie. Without it, your PM plan is just guesswork. With it, you can start assigning the right tasks to the right assets at the right intervals, and that’s how real maintenance improvements begin.

Step 2: Define Maintenance Tasks and Schedules

With your equipment audit complete, the next step is to decide what needs to be done and how often. Every asset in your facility should have a list of preventive maintenance tasks matched to a realistic, data-informed schedule. This is where you translate historical failures and field knowledge into an organized, actionable plan.

Start with the manufacturer’s documentation. Most original equipment manufacturer (OEM) manuals include a section on preventive maintenance that outlines recommended tasks, service intervals, and critical points of attention. These guidelines provide a solid baseline, especially for newer equipment still operating under typical conditions.

But in real-world production environments, ideal conditions are the exception, not the rule. Usage patterns vary. Environmental stressors like moisture, dust, heat, or residue buildup speed up wear and tear. That’s why you’ll need to adjust the manufacturer’s guidelines based on how your equipment is actually used on the floor.

Work with your maintenance team to build a detailed task list for each asset. Include recurring preventive maintenance activities such as:

- Cleaning and lubricating moving components.

- Inspecting belts, chains, motors, and gearboxes for wear.

- Replacing consumables like seals, screens, or gaskets before failure.

- Calibrating sensors, scales, and control systems.

- Verifying proper function of interlocks, emergency stops, and safety switches.

- Testing performance thresholds, such as airflow, pressure, or temperature settings on key systems.

- Reviewing software interfaces and resetting error logs where applicable.

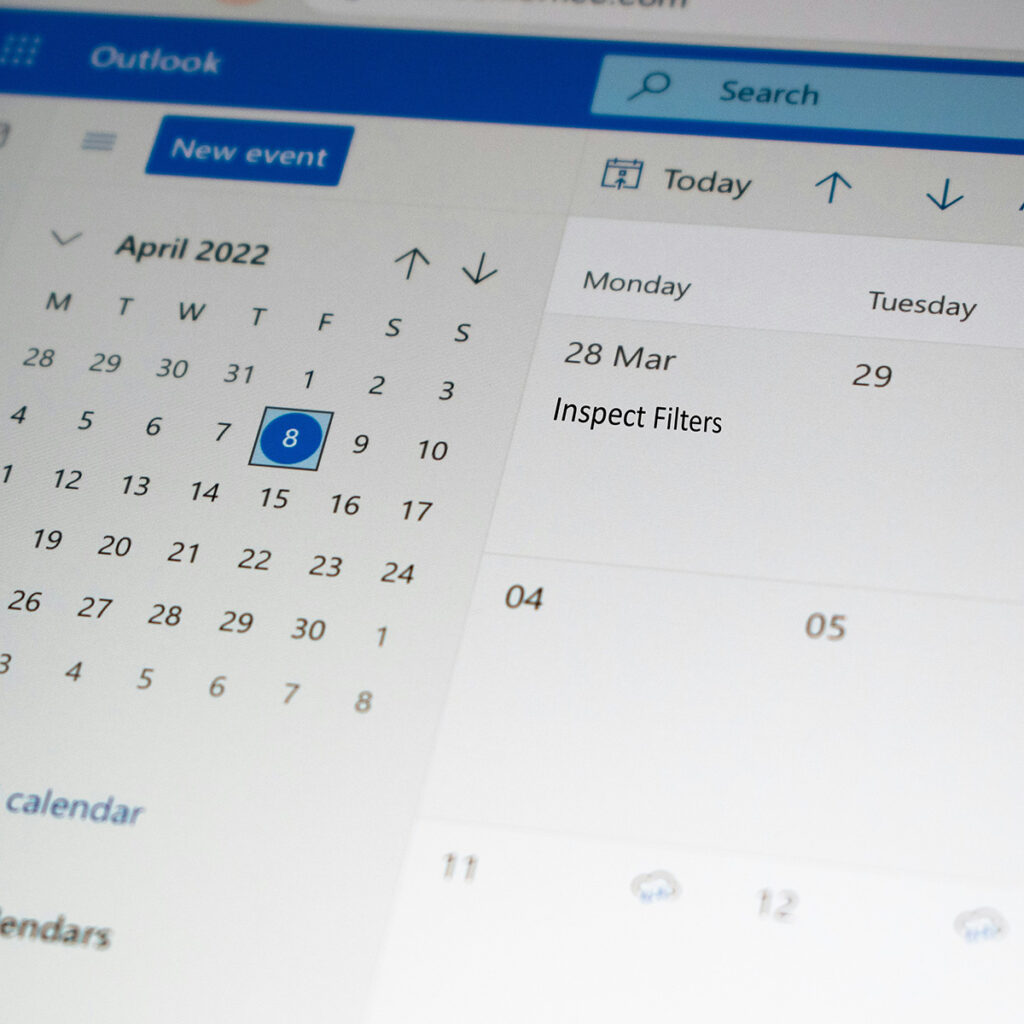

Once you’ve defined the tasks, assign service intervals. Most times, you’ll need to mix several scheduling models to match operational needs. Common approaches include:

- Calendar-based schedules, where tasks occur weekly, monthly, or quarterly.

- Usage-based schedules, triggered by runtime hours or production cycles.

- Condition-based schedules, initiated by specific thresholds such as vibration, temperature, or pressure readings.

Many facilities find that a hybrid approach works best. For example, you might inspect filters every 30 days but only replace them after 200 hours of use or when airflow drops below a certain level. This allows you to avoid both over-servicing and under-servicing, which can waste time and materials or lead to preventable failures.

Environmental conditions also influence your schedule. In cannabis processing, for example, the high humidity of a drying room can corrode contacts and short out control panels more quickly than expected. If you’re working with powders, sticky extracts, or botanical debris, filters and seals may require more frequent attention. Use your operating environment as a guide for when to tighten or extend service intervals.

As you define your schedule, make sure that task frequency reflects actual risk. A minor piece of equipment that only runs twice a week may not need the same attention as a conveyor that powers your main line. Prioritize based on impact. The goal is to keep everything running smoothly without overloading your technicians with unnecessary work.

This step takes time, but it sets the tempo for your entire maintenance operation. A clear, balanced, and customized preventive maintenance schedule prevents surprises on the floor and builds the kind of reliability that long-term success depends on.

Step 3: Create Standard Operating Procedures (SOPs)

After setting your tasks and schedules, the next priority is standardization. Even the best plan will fall apart if the work is performed inconsistently. That’s where SOPs come in. They provide a step-by-step roadmap for your team to follow, ensuring that every maintenance task is done the same way, every time.

Each SOP should outline exactly what the task is, who performs it, and what tools or materials are required. Be specific. If a technician needs a torque wrench set to a certain value, write it down. If PPE is required, list the exact items and when to use them. The goal is to eliminate guesswork.

A strong SOP typically includes:

- A clear task title and purpose.

- Required tools, materials, and safety gear.

- Step-by-step instructions with visuals, if possible.

- Lockout/tagout (LOTO) procedures when applicable.

- Sign-off or verification requirements.

Visual aids can be especially helpful. Diagrams, photos, or even brief video clips go a long way in clarifying complex steps and improving consistency across shifts or locations. For facilities with multiple technicians rotating between equipment types, these details make a measurable difference.

It’s also important to establish who may perform each procedure and who signs off on completion. In regulated industries, proper documentation and traceability are non-negotiable. Approval workflows should be clearly defined and regularly reviewed to maintain compliance.

Store SOPs somewhere accessible. Whether that’s a digital repository inside your CMMS or printed copies at each workstation, they need to be easy to find and simple to follow. Outdated SOPs can be just as dangerous as having none at all, so establish a process for regular review and revision.

At its core, this step is about creating consistency. When technicians follow the same process every time, your results become more predictable, your risk of human error drops, and your entire operation runs with less friction.

Step 4: Implement a CMMS or Centralized PM System

As your preventive maintenance program grows, keeping track of everything manually becomes less practical and more error-prone. A computerized maintenance management system, or CMMS, brings structure to your maintenance operations. It gives your team the tools to organize tasks, track work orders, and make smarter decisions based on real data.

A CMMS helps organize your entire preventive maintenance operation. It centralizes your maintenance data, schedules, and records while enabling your team to:

- Create and manage task lists for each asset.

- Set reminders for upcoming service based on time or usage.

- Record completed work and keep a full service history.

- Log unplanned downtime and note recurring issues.

- Monitor maintenance costs, labor hours, and parts usage.

- Maintain an audit trail for inspections and compliance.

Getting started begins with data entry. Import your asset register, upload SOPs, and input your maintenance tasks along with their frequencies. Many systems include templates and task libraries to streamline this step. Once your data is in, you can begin assigning responsibilities and setting up reminders for each scheduled activity.

Integration is also key. Your CMMS should align with your production schedule so that maintenance activity doesn’t conflict with active workflows. Planning maintenance during idle times reduces disruptions and helps prevent conflicts between departments. Some platforms even integrate with inventory management systems, making it easier to track parts usage and trigger reorders automatically.

Training is critical. Everyone from maintenance leads to machine operators should understand how to view assignments, log their work, and flag issues. Operators should know how to report unusual equipment behavior or request support. The goal isn’t just to digitize your paperwork but to create a living, collaborative platform for equipment care.

With the right CMMS in place, your preventive maintenance plan becomes more transparent, scalable, and responsive to real-world conditions.

Step 5: Train Maintenance and Operations Staff

An effective preventive maintenance program relies on more than just systems and schedules. It depends on people who are well-trained, well-informed, and aligned in their approach. Without consistent training, even the best-designed program will struggle to deliver results.

Start by building training around the procedures already in place. Technicians should not only understand how to carry out each task, but also why it matters. When they see how regular maintenance supports equipment performance and product consistency, they are more likely to take ownership of their role.

An effective maintenance training program typically includes:

- Equipment-specific maintenance tasks and procedures.

- Safety protocols, including personal protective equipment and lockout/tagout.

- Hands-on instruction under supervision.

- Common troubleshooting methods and diagnostic tools.

- CMMS workflows and proper documentation practices.

Training should also extend beyond the maintenance department. Operators are often the first to notice unusual performance, shifts in temperature, or early signs of mechanical wear. Providing them with foundational maintenance knowledge helps catch problems early and supports a more proactive facility culture.

Establish clear expectations regarding roles and responsibilities. Each team member should know what they are responsible for, who to report issues to, and how their work fits into the broader maintenance strategy. Defined roles reduce confusion and improve consistency across shifts and departments.

Maintain detailed training records to track completion dates, assigned equipment, and individual qualifications. Schedule regular refreshers and update content when procedures or equipment change. As your maintenance program evolves, your training program should evolve with it.

Ultimately, preventive maintenance works best when it’s supported by a skilled and engaged team. Ongoing training ensures that knowledge stays current, procedures are followed correctly, and maintenance remains a shared priority throughout the organization.

Step 6: Monitor Results and Refine the Program

Building a preventive maintenance program isn’t a one-time task. It’s an ongoing process of evaluation and improvement. Once your system is in place, the final step is monitoring its performance and using that data to refine your approach.

Start by tracking key performance indicators (KPIs), such as:

- PM task completion rate

- Equipment uptime or availability

- Mean Time Between Failures (MTBF)

- Maintenance cost per asset

- Number and duration of unplanned downtime events

A CMMS simplifies this process by collecting data automatically and generating reports. Use it to review trends, identify recurring issues, and monitor the performance of specific assets over time. For example, if a particular machine continues to experience breakdowns despite routine maintenance, it may indicate the need to revise task frequency or add condition-based monitoring.

Feedback from technicians and operators is just as important as data. They can offer insights into tasks that are frequently missed, overly complicated, or no longer necessary. If a step in a procedure is routinely skipped, it may suggest that the instructions need clarification, or the timing needs to be adjusted. Encouraging open communication helps uncover these issues before they affect performance, and this real-world data is beneficial for optimizing your maintenance program.

Make changes deliberately and document them clearly. Some adjustments the program might need include:

- Adjusting task frequency based on updated wear data.

- Revising SOPs for clarity or safety.

- Adding condition-based triggers to usage-based maintenance plans.

- Reallocating labor based on asset criticality.

The best preventive maintenance programs are dynamic. They adapt to changes in production, equipment design, environmental conditions, and team structure. With the right metrics and a commitment to continuous improvement, your PM program can become one of the most valuable systems in your operation.

Putting It All Together: Start Strong and Scale Smart

Preventive maintenance is more than a checklist — it’s a long-term investment in equipment reliability, operational stability, and cost control. By taking a strategic, step-by-step approach, you can build a program that works in the real world, not just on paper.

Start with a full audit. Build maintenance schedules that reflect how your equipment is used. Standardize your procedures, organize your data, and train your team to deliver consistent results. Monitor what’s working and keep improving. Whether you’re producing cannabis extracts, dried fruit, nutritional supplements, or ready-to-drink beverages, the principles remain the same.

At Mobius, we’ve helped facilities of all sizes reduce downtime, extend asset life, and optimize performance through smart maintenance practices. We engineer our trimming, conveyance, and automation solutions with reliability and serviceability in mind, making them a natural fit for preventive maintenance programs.

To learn more about how our equipment supports long-term operational success, or to connect with a specialist who can help optimize your workflow: