Optimize Your Harvest with a Cannabis Sorter

Investing in a cannabis sorter, or “bud sorter,” is crucial to scaling your cultivation strategies. Most cannabis users have long associated flower quality with size. Larger cannabis flowers aren’t just more visually impressive than their smaller counterparts, they’re often more potent too.

While the connection between potency and flower size can vary depending on your strain, a larger bud generally includes more terpenes and trichomes. A cannabis sorter helps you to identify the largest, most impressive buds in your harvest quickly and efficiently.

They can also contribute to a more consistent product, ensuring all of your customers get a similar size of bud, and the same value from their purchase. This is critical, especially now when demand for cannabis remains strong despite increasing inflationary pressures and challenging economic conditions. In 2024, revenue from cannabis sales in the U.S. is expected to reach nearly $40 billion, with a steady increase of both medicinal and recreational users, and increased spending per person, as more states legalize its use.

While manual sorting can be a time-consuming process, an automated bud sorter gives you an effective way to streamline your operations, reduce manual labor costs, and deliver precise sorting opportunities.

Used correctly, the right cannabis sorter can help you access more revenue, improve your reputation with customers, and scale your business.

Why You Should Sort Your Cannabis Flower

For cannabis cultivators, sorting buds can be an essential way to increase the value of your crop. By sorting cannabis flowers based on their different sizes, you can determine how to use each bud more effectively in your products.

Larger flowers, which grow higher on the stalk, are more potent than small buds, but the difference is often minimal. Many smaller flowers can possess the same usage effects and terpene profile, making them ideal for various products, including pre-rolls, extractions, and tinctures.

Market reports show that pre-rolls are some of the fastest-growing products in the industry, growing at a rate of 12% year-over-year in the US, and 38% in Canada. Extracts can be equally valuable, as consumers experiment with new consumption methods.

With a bud sorter, you can select smaller buds for high-value products, removing them from the discrimination consumers show to products based on flower size. You can reserve your bigger flowers for direct sales, and your smaller buds for other items. You can even consider creating “popcorn” bud collections for price-conscious consumers.

Sorting your cannabis flower can also help with B2B sales. Although business purchasers aren’t as swayed by the aesthetic appeal of a larger flower, they may be hesitant to pay per-pound price for mixed flower sizes. If they see smaller flowers in a batch, they might ask for a lower price.

In the cannabis processing industry, a flower sorter lets you meet all of their requests precisely, thus improving your bud quality control and bargaining leverage.

Using a cannabis sorter also means you can maintain consistent product quality for each type of product you sell, ensuring each option has a consistent level of potency and visual appeal. Flower sorters even ensure you can meet custom size requests.

A sorter even helps to reduce waste by optimizing your utilization of valuable plant material, and ensuring smaller buds aren’t overlooked.

Explore the M9 Sorter Today.

Manual Sorting vs. Mechanical Sorting

There are two options for sorting buds depending on your budgetary constraints and harvest crop size: manual sorting and mechanical sorting. As you make your choice, be sure to consider your future production volume. During the processing phase, sorting the cannabis buds by hand is laborious and imprecise. Typically, human sorters select the larger flowers from the harvest and call the task complete. They sort into three rough categories (large, medium, and “smalls”) based on visual estimates.

With an automated cannabis flower sorter, a grate or conveyor is typically used to remove the smaller flowers first, followed by the medium-sized flowers, and then the largest. Regardless of the sorter’s design, the smaller flowers pass through the grate slots before the larger material.

The best bud sorters are adjustable and provide additional grate sizes; you can define small, medium, and large however you wish, making it easier to meet downstream marketing objectives.

The Issues with Manual Sorting

With manual, or non-automated sorting, technicians agitate cannabis flowers across a gradient. Flowers fall through a sequence of standardized grate sizes, arranged vertically or horizontally. It’s often difficult to achieve precise sizing because everything is based on visual estimates. Additionally, the manual sorting process is extremely time-consuming.

It requires heavy investment in manual labor, even if you choose a sorter with built-in vibration to help assist technicians. Although manual sorting is cheaper initially than paying for an automated sorting solution, the cost adds up in the long term. The need for an attendant increases operational expenses. To make matters worse, manual sorting can produce variations in products, due to attendant fatigue, mistakes, and their level of experience.

Another drawback is the style of the processing; agitating the flowers back and forth across a grate ruptures the trichome heads. Because trichome heads contain most of the valuable cannabinoids, non-automated sorters compromise the harvest. For large-scale operators, these systems are unacceptable.

The Benefits of Using an Automated Bud Sorter

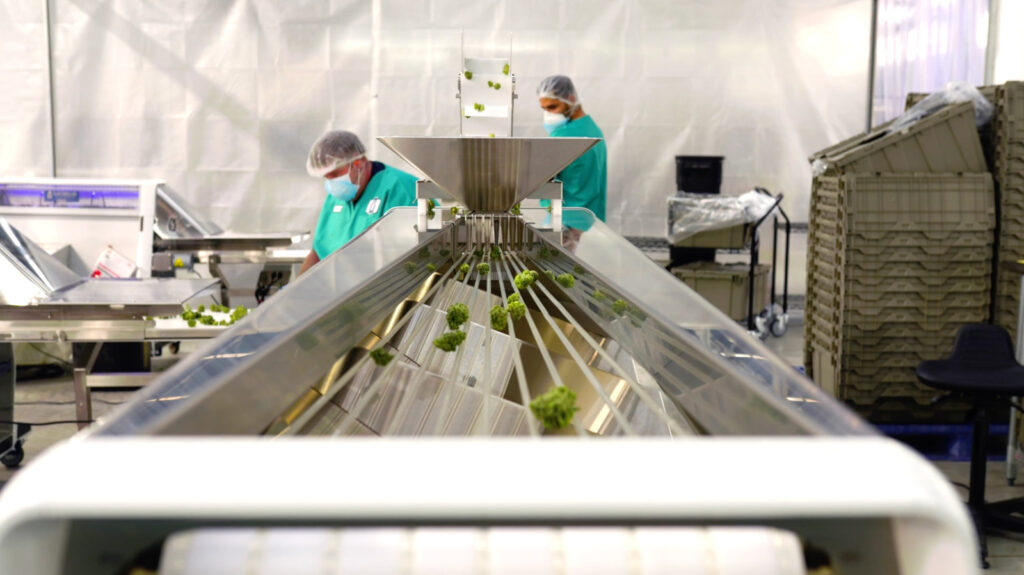

Besides being faster, automated sorters such as the stainless steel Mobius M9 Sorter preserve product quality; they eliminate the need to agitate your flowers across a grate, improving consistency. These “throughput” sorters use conveyors made up of diverging belts to sort flowers more precisely and in a controlled environment.

This means cultivators can ensure they’re accessing the highest quality buds and preserving those valuable trichomes. Automated sorters significantly improve the efficiency of your operation, reducing labor costs and increasing productivity, by removing the need for manual management.

On the Mobius M9, a total of nine belts move product down the line, letting flowers drop through as the gaps between the belts widen. The sorted flowers are collected in bins in order of small to large.

These sorters reduce labor for the cannabis grower and require little attention during operation. They also complement other automation equipment, leading to greater efficiencies. What’s more, a good cannabis sorter can help to ensure compliance with industry regulations. Notably, one study found that 52.4% of cannabis cultivators consider compliance their biggest challenge.

What to Look for in a Cannabis Sorter?

In the cannabis processing industry, all of your equipment should be easy to use, easy to maintain, and reliably meet your production goals. A bud sorter is no different.

Make sure your new equipment meets safety standards and the following metrics, and for more information, reference these tips for buying a commercial bud sorter:

- Prioritize stainless steel: In an era of federal legalization, cannabis producers must ensure they’re complying with Good Manufacturing Practices (GMP). A stainless steel, food-grade sorter will ensure you can adhere to leading standards. Plus, steel is easy to clean with no special tools.

- Look for easily serviceable sorters: Cannabis pollen can adhere rapidly to warm, moving parts. Therefore, cannabis sorters, bud trimmer devices, and similar tools require comprehensive cleaning. The best sorters will be easy to disassemble and adjust for cleaning.

- Ensure simplicity: Automated bud sorters should reduce labor, not increase it. Ensure your solution makes it easy to reduce labor expenditures, with a simple operation mechanism, a large sorting surface, and the ability to integrate with other automation tools.

- Pick a sorter with a long total sorting distance: Long sorting surfaces are essential to ensure you can access both smaller and larger sizes of buds with absolute accuracy. The longer your sorting surface, the more accurate and precise your results will be.

- Look for a gentle solution: A quality bud sorter should use gravity or minor vibration to move the buds. Avoid anything that’s too aggressive, as this could damage the delicate terpenes and trichomes of your cannabis flower.

The Mobius M9 Sorter

With an industry-leading total sorting distance of 78 inches and nine sorting belts, the Mobius M9 Sorter is the fastest, and most precise option available. Featuring stainless steel construction for GMP compliance and easy cleaning, as well as tool-free disassembly, and operator safety guarding, the M9 has everything cultivators need.

With the Mobius M9, growers can achieve exceptional efficiency, with a solution 100 times faster than manual sorting and 4 times faster than the nearest competitor. The sorter can sort 440 flowers per hour and comes with adjustable sorting partitions for unlimited size options.

What’s more, it’s compatible with optional Autofeed Conveyors, ensuring you can easily integrate the system into your automated Mobius harvesting strategy. The Autofeed Conveyor helps move and process your cannabis crop from trimmer to sorter with minimal handling by workers, reducing labor costs and decreasing repetitive strain injuries. Gentle and precise, this high-performance sorter will help to optimize your operations, while preserving trichomes and potency.

Learn more about the unique benefits of the Mobius M9 sorter here.

How to Integrate A Sorter with Full System Automation

One of the main benefits of a leading automated bud sorter, like the Mobius M9, is that it can integrate easily with your existing automation solutions. Assuming you already employ a throughput trimmer, such as the Mobius M108S, a sorter can seamlessly integrate into your operation.

Because of its conveyor-style mechanism, the Mobius M9 Sorter works well in sequence with other throughput equipment, such as Outfeed and Autofeed Conveyors. The complete system begins with the MBX Bucker to quickly separate flowers from the stalks. Bucked flowers then travel into the trimmer via an Infeed Conveyor. From the trimmer, they are pushed onto an Outfeed Conveyor for quality control inspection. Afterward, they go along the Autofeed Conveyor into the sorter, which separates them for further processing.

The key to integrating your equipment is ensuring it operates at equivalent processing speeds. The Mobius M9 Sorter, for instance, can process 440 pounds of dry flower per hour. Given its speed, the M9 is unlikely to create a bottleneck during production.

Final Thoughts

An effective cannabis sorter, particularly an automated solution like the Mobius M9, can be the key to scaling your cultivation processes and increasing your revenue. With these tools, you can improve business efficiency, and enhance the quality of your products.

Contact a Mobius Representative today to learn more about the potential of the M9 sorter, request a quote, or access advice on the technologies that will transform your business.