How to Harvest Cannabis on a Commercial Scale

Harvesting cannabis is easy if you’re a hobbyist. For commercial cannabis growers, it’s a whole different ball game.

A small-time grower can take their time. They might choose to dry trim some cannabis buds and wet trim others or they may choose to trim the entire plant using the same method. And they don’t experience the pressure of staffing or the demand of your retailers.

As a commercial cannabis grower, however, you need a solid plan to get the plants down and packaged for sale as quickly as possible — crop after crop, every time. Each part of your harvest plan needs to operate seamlessly, from the chop to the drying room.

Without a good plan for how to harvest cannabis and hemp, you’re causing yourself headaches and uncertainty, and letting money slip out the door.

So let’s take some time and go over the benefits of an optimized harvest plan.

Time Your Crop Cycle

A successful marijuana harvest starts months before chop day. When you do a good job of pacing your propagation, you’ll have consistent volumes that won’t overwhelm your staff, trimming equipment, or drying space. It starts with knowing your strains (cultivars). You’re probably working with several — possibly all in the same flowering room.

Some cultivars will finish faster than others such as pure sativas. So be mindful of those differences as you forecast your cannabis harvests. (And remember to start plants of the same cultivar together so they’re ready to harvest at the same time.)

Also, keep an eye on your trichomes as your scheduled harvest day approaches. They’re the final word on when to harvest and impact potency levels.

When half of the trichomes look cloudy, it’s time. If they’re starting to look amber, it’s getting late and your crop might not meet consumer preferences. Amber cannabis trichomes from over-ripe flowers give a more sedative effect, and may not be as aesthetically pleasing either.

Advanced cultivators may opt for laboratory testing to determine maximum cannabinoid levels. Cannabigerol (CBG) is the precursor cannabinoid to other important compounds. So when CBG approaches zero, you know the plants have achieved their maximum potency potential.

Should You Chop the Tops First?

The top colas of your marijuana plants mature sooner, developing trichomes earlier than the lower flowers. They mature sooner because they receive more light.

So some growers take the tops down first when they are at their optimal cannabinoid levels. They let the lower marijuana buds go for another week or two so the lowers can achieve their maximum potency too.

This strategy can help even out your harvest flow. But it can also complicate your harvests because you end up harvesting the same cannabis plant twice. Harvesting piecemeal (tops first) can complicate seed-to-sales tracking.

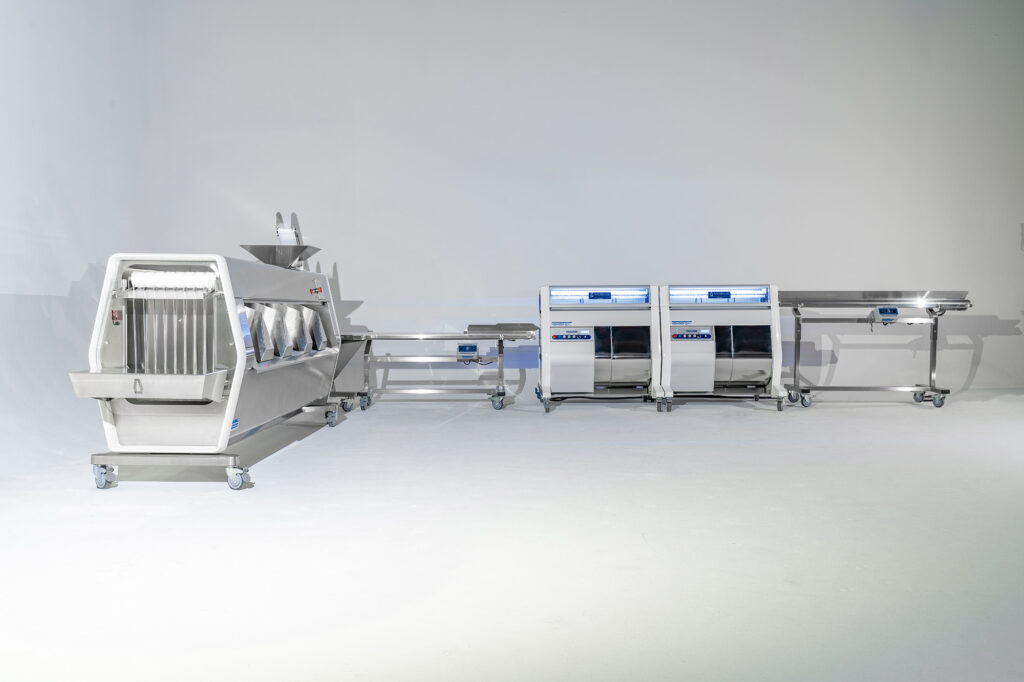

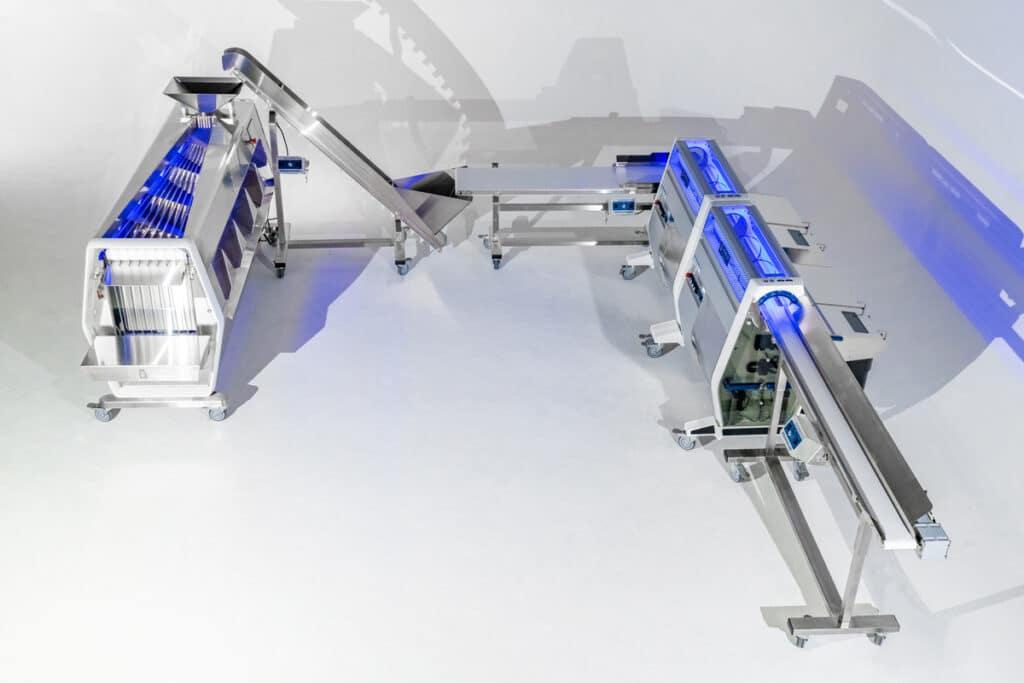

Gear Up with Cannabis Automation Equipment

While you’re crop planning, plan your equipment purchases too. Well-chosen equipment can save you thousands in labor and pay for itself within a few weeks.

There’s a lot to say about the benefits of processing equipment like automatic buckers and dry trimmers, and we’ll discuss other aspects of automated equipment in a bit. But it’s important to mention automation now because it’s important to contact an equipment manufacturer early in the process — long before a big harvest.

Which should you choose first?

- Cannabis trimmers

- Cannabis buckers

- Conveyors

- Cannabis sorters

- Cannabis mill/ Industrial cannabis grinders

Most startup licensees won’t jump to a fully automated line of cannabis processing equipment. They should start with a wet or dry trimmer and maybe a bucker. Experienced operators, however, may get significant ROI by sophisticating their automation and adding conveyors and sorters to the mix.

An expert can help determine the automatic trimmer and additional equipment you need based on your facility size and staffing. If you’re serious about your next harvest, call Mobius now for a free consultation.

Take the 30,000-Foot View on How to Harvest Cannabis

As you devise your standard operating procedures (SOPs), take these four things into account:

Move Plants to People, Not People to Plants

Dozens of trips across a two-acre greenhouse will waste labor and effort. So devise a strategy that minimizes transit time for your workers and reduces your overall harvest time.

High-tech facilities use conveyors that move plants to a headhouse for harvesting. This cuts down on foot traffic, and it also lets staff do their jobs more ergonomically and systematically.

A harvesting station also minimizes handling that damages trichomes (i.e., the cut stalks can be fed directly into a bucker instead of being piled on a cart.)

Even if you can’t use a plant conveyor, you can still spend some time thinking about how to minimize your travel time between your garden and your trimming area. Solving that issue will save you money and stress.

Handle Product Gently

Every time you touch your cannabis flowers, they lose potency. The trichomes rupture, causing terpenes and cannabinoids to evaporate — and all the hard work you put into growing is compromised.

So, if you can avoid repeatedly piling and moving cut-down stalks, do so. The same goes for dumping bucked buds from one container into another. Your auto trimmer should also be functioning well to give you a clean-cut and minimal tumble time.

Another aspect of gentle handling is maintaining optimal temperature and humidity. Don’t expose plants to temperatures above 68℉, and don’t expose harvested plants to moisture and humid environments. Post-harvest moisture can breed pathogens and mold.

Know Your Cultivation Objectives

Are you wet trimming for fresh frozen processing? Dry trimming for-boutique flower? Your answers to these questions will hugely influence how you harvest your equipment and your drying space needs.

There’s no one-size-fits-all processing plan. The following will affect how you process your crop, as well as the other equipment you may need downstream.

- Product intention: extraction, cannabis pre-rolls, or whole flower

- Packaging (bulk wholesale or consumer retail)

- Indoor, greenhouse, or outdoor grow

- Facility layout and drying room capacity

- Weather patterns

For instance, if you’re harvesting for extraction or pre-rolls, the aesthetics of your buds won’t matter nearly as much as if you’re packaging whole-flower for consumer retail. That means you won’t need as close of a trim or as much quality control (QC). In addition, this may dictate your cannabis trimming methodology. Dry trimming tends to be used more frequently in consumer retail applications and for indoor grows, while wet trimming is often used in outdoor and bulk flower applications.

Have a Cleaning and Sanitation Plan

Cleaning is a big part of any harvest. When setting up your facility for the harvest make sure you have a clean work surface and a schedule of cleaning and sanitation. In addition, make sure you have allocated time and resources to cleaning or you could be left short-handed. If you are following Good Manufacturing Practices (GMP) in your trim room, see our GMP guidelines.

Equipment will determine many of your cleaning tasks, as well as your GMP compliance. Some equipment will take more time to clean, disassemble, reassemble, and service. Trimmers, for instance, need significant cleaning not just for the sake of sanitation but also for proper operation.

Look for equipment that minimizes the cracks and crevices which cause plant debris to accumulate. Forward-thinking equipment designers account for cleaning and maintenance — not just how the machine operates in the moment. Ask your manufacturer what cleaning intervals you can expect with your new machines.

Further, assure your equipment is compatible with the approved cleaning agents you plan to use. Stainless steel stands up to most commercial cleaners and pressure washing; lesser materials may not.

Plan for Drying

Many cultivators overlook drying when designing their facilities and SOPs. How to dry cannabis is another trickle-down consideration based on your cultivation objectives.

If you choose to dry trim, your cut-down stalks will head to the drying room immediately after harvest. This trimming plan requires a drying room outfitted with lines from which to hang the plants and sufficient space for whole plants with adequate airflow.

A wet trim drying room is very different — you’ll want drying racks on which to arrange your detached flowers. Whether these are baker-rack trays or hanging baskets, make sure they’re easy to clean.

Many operators choose wet trimming in part because it reduces the floor space they need for a drying room. Detached flowers take up less space than hanging stalks and dry more quickly than intact stalks waiting for dry trimming.

Regardless of your room choice, make sure you have good air circulation and proper environmental conditions (65-75 F/40-50% humidity). Mold and bud rot can develop if your drying space is too damp or has poor air circulation. If the drying area is too dry or hot, you’ll compromise your product quality.

Train Your Staff for Success

Your SOPs become great training tools when it comes time to onboard new employees. You can use them outright for training or draw from them to create specific training manuals. Regardless, everyone on the floor needs to know what’s going on.

Employees need to understand the entire harvest/processing plan — not just their specific tasks. They need the big picture, and the ability to switch up roles from QC to machine operation to packaging.

Make sure to have enough people on hand too. Your equipment manufacturer can help you understand how many people you’ll need and how fast you’ll be able to harvest/trim.

Steps to Harvesting Cannabis and Hemp

With so many ways to harvest, it’s impossible to lay out a step-by-step harvesting sequence that applies to everyone. So here’s an example of a wet-trimming plan in a typical indoor facility.

1. Chop

Cut the stalks individually, starting at the base of the plant. It’s best to harvest at the end of the nocturnal period (early morning) before the plants start photosynthesizing and cycling nutrients up from the growing media.

2. Buck

Separate the flowers from the stalks using a cannabis bucking machine. A mechanical bucker pulls each stalk through a hole, forcing the flowers to pop off the stem.

A cannabis and hemp bucking machine will cut down significantly on bucking labor by about 85% (one bucker replaces about 7 people). Although it is important to optimize your bucking workflow and labor to make it most efficient.

3. Feed the trimmer

A wet trimmer or throughput trimmer is ideal for processing fresh cannabis flowers. Here’s how it works: untrimmed buds go in one side of a bladed tumbler and emerge out the other side nicely trimmed.

You’ll need a person to feed fresh flowers into the tumbler handful-by-handful at an even pace or a conveyor to do the same. A conveyor makes the feed more consistent and requires less attention from the operator.

4. Operate the trimmer

It’s important to closely monitor your cannabis trimming machine to make sure you’re getting the right trim: not too close and not too leafy.

The tilt angle of the tumbler influences how fast flowers move through the system. If they’re spending too much time in the tumbler, they’ll be trimmed too close and damaged.

Make sure you’re getting the results you want and adjust accordingly. Depending on your machine, you may be able to adjust the tumbler speed, tilt angle, shear band speed, and vacuum power.

You’ll want to harvest at the same rate as you’re trimming. Flowers trim best when the leaves are firm and freshly cut. If you’re harvesting and letting flowers sit for a few hours, the trim quality will drop.

5. (Clean the trimmer every few hours)

Trimmers need regular cleaning for the best results. While they may cut down on labor by as much as 900%, you do need to spend time on cleaning tasks. Some trimmers like the M108S are easier to clean than others and allow you to save valuable time in the cleaning process.

Look for trimmers that are easy to disassemble and rugged enough to stand up to some mistreatment from hasty employees. Expect to spend a half-hour cleaning your trimmer for every four hours you spend operating it although, with the Hot Swap Kit, this time can be greatly reduced.

6. Inspect the results

On the outfeed of the auto trimmer, you’ll want a few humans for quality control. Inner leaves (crows feet) are impossible to access mechanically, so your staff will need to snip those leaves as the flowers exit the machine.

7. Sort

You may want to sort your flowers by size. When they’re sorted by size, you have more control over how you use your crop (you may want to use the small flowers exclusively for extraction), and you’ll ultimately get more money from your harvest. If you’re sorting, a mechanical sorter makes the task a breeze.

8. Arrange for drying

Space the trimmed flowers evenly on drying racks and place them in your drying room, which should be climate-controlled at around 65-75°F and 40-50% humidity.

(After a day, you’ll want to turn the flowers on the racks to avoid flat spots.)

9. Collect your trim

Make sure to save your trim for extraction. Trim is an important sub-product of the harvest that’s often overlooked. A good cannabis trimmer, such as the Mobius M108S, is designed to preserve trim quality for better extracts.

Again, it’s impossible to summarize all harvest situations. If you’re dry trimming, you’d hang the cut stalks and carefully wait for the ideal moisture content (9-10%) before your process in a dry batch trimmer, for a throughput wet trimmer or combination trimmer you will increase the moisture to (13-14%) for dry trimming. And you’d probably skip the mechanical bucker, which can be hard on dry, delicate flowers.

Discover the Hidden Benefits of Automation

When you automate with a mechanical cannabis trimmer or cannabis bucker, a lot of good things happen for you and your employees.

Yes, labor drops. You’ll spend less. But you’ll also have an easier time staffing — finding eight good people to hire is a lot easier than staffing a trim crew of 40.

As a result of fewer people, you’ll have less theft. Harvest time is when employees are most tempted to divert product, and fewer people means less loss.

Moreover, employees feel better. Their jobs are easier, more interesting, and less repetitive. There’s a technical element of equipment operation that turns them into a skilled labor force ready for professional development. The harvest feels less stressful and more organized.

The overall employment environment of your operation changes with better automation too. Instead of a hunched-over trim crew digging through heaps of weed, you’re an industry-leading operator consistently delivering excellent cannabis.

Most of all, you get predictability with automation that you can’t achieve without. A well-planned processing line will churn out high-quality flower-like your trim crew never could. You’ll get your plants down and out the door faster than ever before.

If you’re ready to try a mechanical trimmer — or ready to take the next step to full automation — call Mobius today. We can help pair you up with equipment that’s right for you — not a generic one-size-fits-all solution.

Our experts have the real-world experience to provide practical solutions that meet your unique needs.