Evolution of Cannabis Cultivation: Machine Trimmed vs. Hand Trimmed

We dive deep into the ongoing debate: machine-trimmed vs. hand-trimmed cannabis. There are valid reasons why a cultivator may choose one method over the other. Machine trimming technology has evolved rapidly in recent years. However, many arguments against machine trimming are based on a limited understanding of the products now available on the market. Still, hand trimming can be a viable choice for small-scale growers and micro-cultivators.

Some brands believe that a hand-trimmed product conveys higher quality. Hand trimming allows cultivators to pay incredible attention to detail and treat each bud uniquely. However, trimming by hand is extremely limited in scale.

As your brand grows, you may feel left with a difficult dilemma. Continue to commit to hand-trimmed products and limit your business’s ability to grow, or pivot towards machine trimming with its ability to handle vastly larger quantities and trust in its hands-off approach. With commercial trimmers like the Mobius M108S, cultivators can preserve hand-trimmed quality in their products without compromising on scalability. However, it can still be helpful to explore the differences between trimming methods to learn how you can improve production workflow and potentially scale your operation.

Back to Basics—Trimming 101

Though many cultivators consider harvesting one of the most important processes in their business, it’s far from the end of creating a compelling product. Trimming is essential for producing and delivering a consistent, quality product to consumers.

Cannabis trimming involves meticulously removing excess stems and leaves from harvested buds. Cultivators can use various dry trim and wet trimming methods to refine their final product’s appearance while optimizing its potency and overall quality. Depending on your operation workflow and desired product offerings, you may consider a dry trimmer, wet trimmer, or a hybrid trimming machine that can process various moisture levels.

Trimming buds provide several benefits:

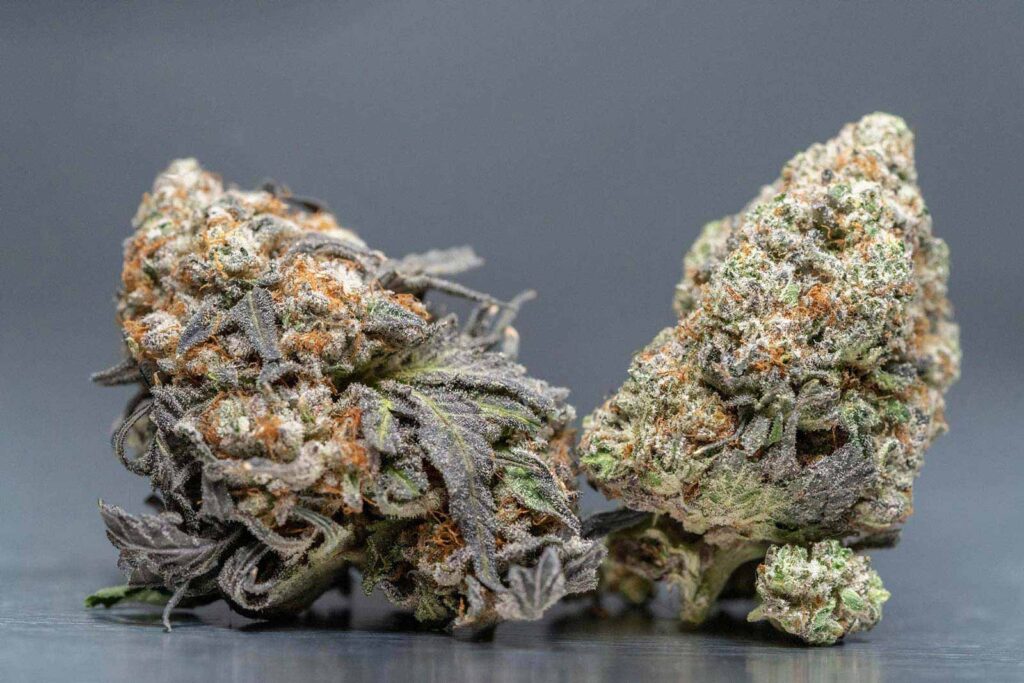

- A more appealing product. A properly trimmed bud is more appealing for consumers with a uniform appearance and showcases the abundance of trichomes.

- Reduced moisture content. If you wet trim, the resulting buds will dry more quickly and evenly, reducing your chances for mold or mildew growth.

- Improved taste: If you dry trim, you limit the amount of chlorophyll, which can contribute to a grassy taste.

- Optimized potency. The smaller sugar leaves surrounding the buds contain fewer trichomes. By removing them, you’ll be left with the most potent part of the plant.

A Thorough Look at Hand Trimming

Hand-trimmed cannabis is carefully produced using manual practices and specialized tools, such as specific scissors, harvesting trays, and drying racks. This method requires skilled labor and a keen eye for detail, making it a popular choice for those who prioritize craftsmanship in their products.

During hand trimming, professionals carefully remove excess leaves and stems from each bud so only the trichome-rich flower remains. Unfortunately, given the level of care and attention required for each bud, 74% of growers in one study said they consider hand-trimming to be their most significant post-harvest challenge.

The Benefits of Hand Trimming

- Craftsmanship trimming: The practice of hand trimming is often associated with skilled craftsmanship because it requires meticulous attention to detail, with each bud carefully examined. Though the same level of accuracy can now be achieved with automated methods, some smaller-scale cultivators still prefer the manual approach.

- Exceptional quality checking: Small batches of plant material trimmed by hand benefit from high levels of attention, and stringent quality checks. Hand trimmers can ensure every bud meets the desired quality standards and adheres to requirements for consistency.

The Cons of Hand Trimming

- Time-consuming: Hand trimming is an intensive manual process, which takes a significant amount of time to do well. It’s not a practical option for large-scale cultivation operations needing rapid results and turnover.

- High production costs: Hand trimming often requires significant skill and experienced workers. The need for professionals to perform the trimming process drives up labor and operating costs.

- Product variability: The outcomes of hand trimming are challenging to keep uniform. The results you get may vary depending on each trimmer’s pace, experience, and technique. This can lead to inconsistencies in each harvest and between different batches, which impacts consumer trust and brand loyalty.

- Not scalable: While hand trimming is attainable on a small scale, it cannot be done for larger harvests or commercial-scale farms.

Everything You Need to Know About Trimming Machines

While the craftsmanship allowed by hand trimming has long appealed to some cultivators, business leaders no longer need to choose between quality and scalability. An advanced trimming machine, such as the Mobius M108S, offers specialized features to preserve the full potential of each plant.

With the right automated trimming machine, cultivators can remove leaves and stems from cannabis buds carefully and effectively. An aerated process allows machines to remove undesirable plant material safely and gently without harming the trichome-rich flowers. Unique to the Mobius M108S trimmer, the AirThread Tension Tumbler and advanced blade system provide a trim like no other.

In fact, when comparing the M108S to hand trimming, lab results show that flower trimmed in the M108S retains a higher total potency percentage (25.2% compared to 22.4%) and a higher percentage of total terpenes (1.61% compared to 1.64%).

Of course, the right equipment is essential for enhancing the outcomes of machine-trimmed cannabis. Machine trimmers come in a variety of models, and can be customized with various accessories, including conveyors and sorting systems for full-scale workflow automation.

The following characteristics matter most when selecting a machine for scalable, high-quality production:

- Feed rate: The speed of an automated trimmer isn’t nearly as important as its feed rate. Speed can vary depending on the weight of wet or dried flower. However, an excellent feed rate ensures quick and efficient outcomes regardless of the moisture content or strain.

- Time to clean: The best trimmers are easy to clean and maintain. They reduce waste and improve productivity.

- Trim quality: The leaves and plant material removed from your flower still have value for use in extracts and other substances. A quality trimmer will ensure you can retain your trim to use for other applications. This increases the return on your investment.

- Labor requirements: A machine trimmer greatly reduces the number of workers needed as compared to hand trimming. You’ll save money on labor and operating costs.

The Benefits of Machine Trimming

When it comes to collecting perfectly trimmed cannabis, many cultivators are concerned about the concept of passing their solution over to a machine. However, many of these concerns are based on myths from the cannabis industry, which have lost their validity over the years as automated solutions became the norm.

Innovation in the trimming landscape and the rise of solutions like the Mobius M108S ensure cultivators can leverage a host of benefits with no downsides. Some of the most significant benefits include:

- Efficiency: Perhaps the greatest benefit of machine trimming is efficiency. An automated machine trimming solution significantly reduces the time and labor required for trimming. This allows cultivators to streamline their production process. With a steady feed rate, larger harvests can be processed in a shorter amount of time.

- Quicker time to market: Because flowers can be more efficiently and rapidly prepared for consumption, this significantly improves time to market. With a shorter harvest-to-sale cycle, products reach consumers when quality is still at its peak. Flower is processed in a fraction of the time, which is particularly important in an industry where timing can impact your market competitiveness.

- Time saved: Time saved on the trimming process translates to time that can be spent elsewhere—on creating extracts or prepping to process the next harvest.

- Scalability: As mentioned above, hand trimming isn’t a viable option for large harvests or scaling businesses. Investing in a machine trimmer allows you to scale your business and process larger quantities of flower more efficiently, leading to increased profit potential.

- Consistency: Machine trimming eliminates the risk of potential inconsistencies, ensuring a consistent trim level, appearance, and potency across different batches and harvests.

- Cost savings: While an initial investment in machinery can be substantial, that investment is paid back after just a couple of harvests. The long-term cost savings can be up to 90% when you use a trimming machine. Reduced labor expenses, of up to 94%, and increased production capacity lead to a higher return on investment and lower operational costs.

- Predictability: With an automated strategy, it’s easier to predict harvest quantities and yields and prepare for consistent sales. You’ll be able to align your sales strategies according to your harvesting and production times.

The Evolution of Cannabis Trimming

The practice of hand trimming cannabis has been a cornerstone of the industry, ensuring precision and a personal touch to the final product. Over time, the rise of technology has brought forth innovations that challenge the status quo. Machine trimmers, once seen as inferior, have undergone significant advancements, bridging the gap between the artisanal quality of hand trimming and the efficiency of automation.

Early generations of machine trimmers struggled with a handful of problems. They couldn’t offer the same attention to detail as hand-trimming alternatives, and some machines offered limited customization options. However, this is no longer the case.

The Mobius M108S, for instance, is the first automated cannabis trimmer on the market to match hand-trimmed quality. It uses a patented AirThread Tension Tumbler to rapidly and accurately trim plant material, with 50% more blade access as compared to traditional sheet-metal tumblers.

The Triflex Blade system in the M108S offers the same precision and dexterity as a pair of trimming scissors. Designed to replicate the shearing action of scissors, surgical-grade stainless steel bed knives flex against helical blades, with no gaps or dead spots. The increased access to the blades provides a close trim while reducing the amount of time products need to stay in the machine. Moreover, the solution is suitable for both wet and dry trimming.

A scalable setup ensures companies can create the ultimate workflow for their needs, using hybrid models or fully automated systems. As your business grows, you can easily add an additional machine to your production line. The M108S trimmers can also be connected in tandem with just a few easy steps. Tandem trimmers provide a greater throughput and more top-quality trimmed flower than two separate trimming machines. And up-stream prep options can improve yields and volume output.

You can even change trimming settings in real time, adjusting tumbler and blade speeds, tilt angle, and suction level. This way, every cultivator can dial in the trim level, fine-tuning the settings based on moisture level, strain, and quantity, resulting in buds with a hand-trim quality in a fraction of the time.

Revolutionizing Yield with Machine Trimming

Today’s cultivators no longer have to choose between exceptional quality and scalability. With the right machine trimming solutions, you can achieve the same level of quality (if not better), while enhancing capacity and throughput.

Saving you time and labor, the Mobius M108S gives you complete control over the end product. Automated trimming solutions are also highly precise, ensuring that your buds rival hand-trimmed ones in appearance, potency, and quality.

With a higher level of consistency and a greater value from your yields, the Mobius M108S trimmer is a customizable solution that can be tailored to fit your needs, allowing you to maximize efficiency and productivity. Easy to maintain and use, it’s a reliable choice for any grower.

Speak to one of our Mobius experts and discover the trimming benefits of the Mobius M108S today and feel confident in making an informed decision for your business.