Automation

Automation in the Cannabis Industry: Why now?

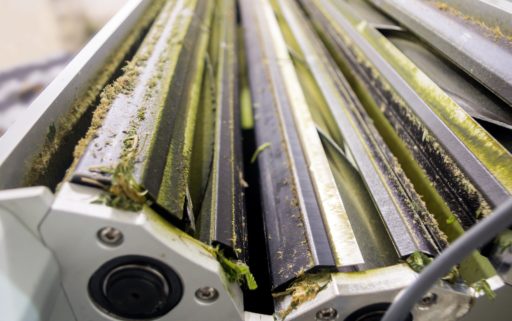

Automation in the cannabis industry was inevitable. While wholesale prices drop in places like Washington, Oregon and Colorado, automation is now the primary way that cannabis facilities are able to lower the cost of production, ensure product consistency, and maintain QA standards.

Read More4 Ways To Stay Competitive When Cannabis Wholesale Prices Drop

Wholesale prices for cannabis peak within a year after legalization, then drop fast. There are variations in the timeline and steepness of the drop-off, but it WILL happen. The question is how do you set your business up to continue to be competitive, flourish, and grow?

Read MoreCLEANING: The Black Hole of Time and Money (Until Now)

Almost as critical to your operation as feed rate: how fast can you CLEAN it? How many work hours does it take to clean your equipment? How long does it take to get it cleaned, and back into operation?

Read More4 Reasons the Commercial Cannabis Industry NEEDS Automation

Automation is already happening in the cannabis industry, and will continue to become the norm. Continue reading the 4 reasons why automation is a good thing.

Read MoreThe Argument for Tandem

A few reasons why running the Mobius Trimmer M108 in tandem is a better, more efficient way to process large commercial cannabis harvests than running two machines separately.

Read MoreGMP: Not just for quality assurance anymore… It’s MARKETING

No commercial cannabis company would seek GMP certification just for a marketing win, but if certification was already in the pipeline, it makes sense to leverage that into PR and content as well.

Read More4 Things You Can Do to Jump-Start GMP in your Commercial Cannabis Facility

Four different steps a commercial cannabis facility can take to ensure production is in keeping with GMP, or Good Manufacturing Practices, and how to implement these in a current operations schedule to create efficiency and consistency.

Read More