Maximizing Cannabis Yields Through Automation

As the thriving cannabis industry continues to grow, cultivators need to find ways of not just improving the quality of their product, but the quantity too.

Maximizing cannabis yield requires more than just planting additional seeds. Business leaders need to optimize every aspect of their cultivation operations, from their strategies for plant growth to their post-harvest procedures.

Often, this means taking advantage of the latest technology to streamline the cannabis cultivation journey and ensure the most value is derived from each plant and every harvest.

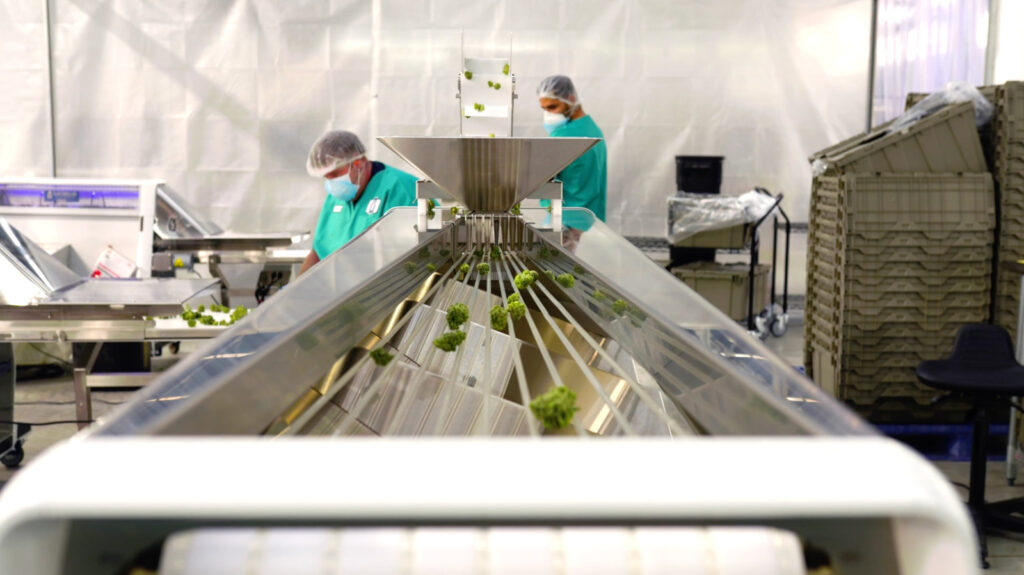

Leveraging automated technology for post-harvesting processes like bucking and trimming can help boost crop yield and quality, give you an edge over the competition in your market, and even increase your revenue while lowering operating costs.

Many innovators in controlled-environment agriculture and horticulture already leverage automation to enhance their workflows. According to one study, up to 70% of specialty crop growers invest in robotic process automation.

Here, we will explore the benefits of implementing automation into your cultivation and post-harvesting operations and discuss the strategies you can use to maximize overall yield.

The Importance of Efficient Processing in Maximizing Yield

Achieving a higher yield is a multi-faceted process. The best results come from a combination of strategies, from choosing the most durable and resilient cannabis seeds for bigger plants to feeding plants advanced nutrients to facilitate growth and even designing the optimal grow room and workflow for your post-harvest production.

Every stage of growing cannabis is crucial, from the vegetative stage to the flowering stage. However, it’s also important to ensure you’re using the right harvesting and post-harvesting techniques.

An effective post-harvesting strategy is critical for preserving the integrity of the plant material and for enhancing its value and quality. Efficient post-harvest processing involves a series of steps, from drying and curing plant material to trimming and packaging the product.

Each step needs to be optimized to preserve the quality and characteristics of the plant while also increasing its shelf life and customer appeal.

A meticulous process means producers can ensure their cannabis plant retains its potent cannabinoid profile and terpenes, which are key factors in achieving premium market prices.

Effective and precise trimming ensures the final product is aesthetically pleasing and potent. Even proper packaging ensures the product can last for as long as possible without losing quality.

However, the precision required in post-harvest processing means the experience is often labor-intensive and time-consuming, making it difficult to scale operations. This is where automation comes into play, ensuring consistent quality and increasing the efficiency of the process.

Automated machines can process cannabis much faster than humans can and help mitigate the risk of human error and contamination. What’s more, with the right machinery, cultivators can ensure they get the same results from an automated system as they would from a team of workers.

The Benefits of Machine Trimmers in Cannabis Processing

Manual post-harvest processing is commonplace among smaller cannabis growers, but it’s simply not feasible for large-scale cultivators and commercial facilities. Operating a high-production facility while maximizing cannabis yield requires leaders to invest in equipment that optimizes and augments their workforce.

Processing equipment, such as machine trimmers, can rapidly transform freshly harvested plants into trimmed flowers, ready for drying, curing, packaging, and further processing for other applications.

The benefits of machine trimmers in cannabis processing include:

Increased Quality & Quality Control

An attentive “hand trim” has always been the quality benchmark for boutique cannabis production. However, trim crews suffer under high volumes, and attentiveness—the key factor in manual trimming—gives way to fatigue and inconsistency. A bud trimmed by hand at the beginning of a shift may not resemble one trimmed at the end of one. Consumers will quickly notice the differences in quality between batches.

Today, mechanical cannabis trimmers deliver a better-quality trim than their human counterparts: close, gentle, and easily controlled with adjustable settings. Batch after batch, each bud is trimmed without any degradation in quality or consistency.

Bigger Yield

A quality trimmer increases yield because it enables you to utilize your entire harvest and trim smaller flowers. Small flowers were previously considered by-product material (i.e., “trim”) because trimming them by hand was not cost-effective. That is, small flowers did not add enough weight to the harvest to justify the trimming labor.

Now, the smallest flowers (which would have otherwise been wasted in the past) are recaptured and sorted out for suitable products (e.g., pre-rolls, extracts). This generates a significant increase in harvest weight without additional labor, as well as increased revenue potential.

Reduced Labor Costs

Machine cannabis trimmers empower a smaller workforce to do more: cultivators who implement automation observe manual labor reductions and reduced product losses. Of course, results vary, and calculating your labor efficiency and savings depends on your current processing volume and equipment.

The largest gains in efficiency come from implementing additional automation equipment with your machine trimmer. You can round out your automated workflow with a bucker, sorter, mill, and conveyors, leading to further operational improvements. Other equipment acquisitions primarily increase product quality, quality control, or marketability, making the process less labor-intensive overall.

Better Marketability

Automation makes production more predictable and puts fresh products on the shelf with greater consistency.

A mechanical trimmer like the M108S allows you to dial in your settings based on the cultivar and moisture levels, as well as control speed and suction. As a result, you can trim each harvest to achieve the same levels of consistency and appearance. Producing consistent flower brings better marketability to your brand for selling to dispensaries and for consumers.

Benefits to Employees & HR

A mechanical trimmer reduces repetitive strain injuries, improves posture, and stimulates professional development. Employees develop new skills as equipment operators and feel valued rather than replaceable. In turn, they are more committed to their jobs and less likely to leave for other positions.

Automation in the marijuana industry also allows business owners to compensate their staff better and employ fewer but more skilled people. This staffing strategy helps limit the uncertainty of workers around harvest season and minimizes the risk of contamination associated with a large staff in the facility.

Speak with an automation specialist today.

Leveraging Automation for Maximized Yields and Enhanced Processing Efficiency

Cannabis Buckers

A bucker is the first step in the processing workflow. A cannabis plant is run through the machine, and the bucker removes the flowers from the stalk so they can be mechanically trimmed.

This technology helps cultivators to achieve maximum yield, by minimizing waste and maximizing plant utilization, while accelerating the processing journey. Rather than rely on workers to buck by hand—which is inefficient and can result in missed buds—a machine bucker quickly and gently removes all the flowers, now ready for trimming or drying.

Cannabis Trimmers

Frequently, cannabis trimmers, or bud trimmers, are the first product companies will invest in when looking for ways of maximizing cannabis yields with automation. Often, these solutions deliver the greatest efficiency gains and help to minimize unnecessary labor.

A quality trimmer will increase yields by preserving more of the smaller flowers that human trimmers would have passed off as non-trimmable plant material. These smaller flowers take too much additional time to trim to be profitably marketed as loose flower. But with machine trimming, these smaller flowers can not only be used in further processing applications like pre-rolls and extraction but they also can be sold separately. By using as much of the plant as possible, cultivators can create additional profit sources from flower that would have otherwise been wasted.

The Mobius trimmer also gives you increased control for both dry trimming and wet trimming, with adjustable blade speed, tumbler speed, vacuum power, and tilt angle. When you are ready to increase your production capacity, an additional M108S can be run in tandem to more than double your throughput.

Sorting Equipment

Sorting through your cannabis harvest can be one of the most time-consuming processes for a cultivator and their team. However, it’s also critical to ensure you deliver consistent products and quality to your customers and make the most of your harvest.

A mechanical sorter helps you sell your harvest more effectively and profitably. A sorter divides your flowers by size, so you can distinguish between premium “top flowers” and smaller buds that can be used for pre-rolls and extractions. By sorting out as many usable buds as possible, you can use more of your harvest for profit instead of it going to waste.

Products like the Mobius M9 Sorter ensure you are keeping the flowers separated by size so you can charge premium prices for your high-quality buds, having removed the smaller flowers from the mix.

Buyers who seek large flowers are less likely to request a lower price because the smaller flowers have been removed. Buyers seeking smaller flowers know they are not overpaying for large flowers they do not need for their intended processes.

With the addition of a sorter, the processing line can be fully automated with no worries about scaling to accommodate future growth. As your business expands, so can your automation line with the addition of more machines.

Conveyor Systems

Conveyor systems are another excellent tool for automating your post-harvest processing strategy. They eliminate the need for employees to manually facilitate the movements of plants and materials and help to perfect the feed rate into your cannabis trimmer.

Mobius cannabis conveyor systems optimize your team’s workflow by keeping everything moving smoothly in your environment. More importantly, they can also help improve the quality of your final product. When a throughput trimmer is fed manually—handful by handful—the inconsistent feed rate yields an inconsistent trim. A conveyor helps smooth the feed, so all the material has the same residence time inside the tumbler.

This results in a highly consistent product and helps to optimize your entire team’s workflow. Some conveyors can even be integrated with a range of other automated equipment.

An outfeed conveyor creates an assembly-line work area for quality control. As the trimmed flower passes by, employees can inspect and manually snip any “crow’s feet” that are impossible to remove mechanically.

Choosing the Right Automated Equipment

Choosing the right equipment for your cannabis operation can be complex. Working with an expert can help you assess your environment and make an educated choice about the solutions you need, leading to better results and a higher yield.

That being said, there are a few core factors you should keep in mind when making your choice:

- The scale of your operations: The larger your business, the more power you’ll need from your automated systems. You may need a larger trimmer or bucking system to accommodate larger volumes of plant material. You may even need to consider combining multiple machines, conveyors, and solutions as your organization evolves.

- Budget: When purchasing automated post-harvest processing equipment, the common rule of thumb is that the more advanced your needs are, the more you can expect to pay. However, it’s important to balance the cost of your solutions with the money and time you’ll save by automating critical tasks.

- Specific processing requirements: Assess your current workflow carefully, and ask yourself what matters most to you in your operations. Do you need an automated trimmer with a specific throughput capacity? Are you looking for a solution that adheres to GMP guidelines, and offers a specific level of customizable trimming precision?

- Ease of maintenance: Maintaining automated cannabis post-harvest processing machinery can be time-consuming and expensive if you make the wrong choice. Look for solutions that are easy to disassemble and clean, and ensure replacement parts are available whenever you may need them.

Maximizing Cannabis Yields with Automation

The best cannabis cultivators are always looking for the most effective methods of achieving a high yield. Maximizing yield means maximizing your potential for revenue and growth in this competitive industry. However, there’s a lot more to getting the most out of your cannabis harvest than you might think.

Automating aspects of your cannabis post-harvest processing strategy can help you not only boost your yield, but also improve the quality of your product, reduce operational costs, and minimize disruptions within your organization.

Every cannabis grower has a unique process when it comes to maximizing cannabis yields. How you implement automation into your strategy will depend on your workflow dynamics and various other factors. Often, to get the best results for your cannabis cultivation and processing strategy, it’s helpful to speak to the experts.

The representatives at Mobius have helped many clients choose post-harvest processing equipment that maximizes their yields and return on investment. Talk to one of our experienced experts about your production goals, and they can help you analyze your workspace, operating procedures, and opportunities for maximizing cannabis yields.