How to Get the Most Profit from Each Harvest: Sorting by Bud Size for Maximum Yields

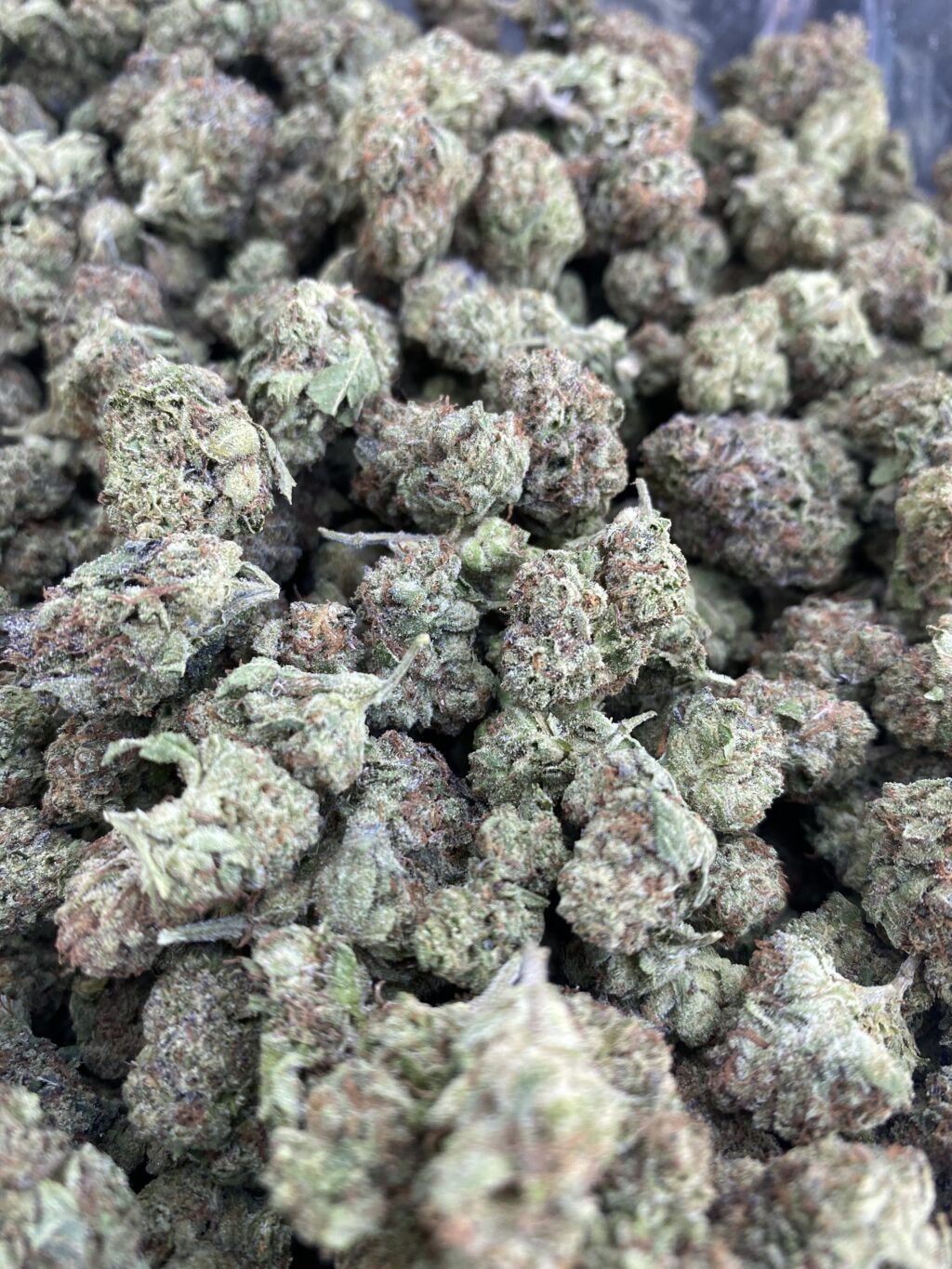

Sorting cannabis by bud size is an essential step for maximizing yield, preserving quality, and increasing profits. By categorizing flower buds into A buds, B buds, and shake or trim, cultivators can optimize pricing per pound, ensure product quality and consistency, and streamline post-harvest processing.

This article explores the impact of bud size on profitability and efficiency, highlighting how commercial processors can benefit from automated sorting solutions to deliver premium, consistent flower.

What Are the Different Cannabis Bud Sizes?

Understanding the distinct categories of bud sizes helps cultivators maximize their harvest. Each size category has unique characteristics and market values that influence how they can best be utilized. Sorting cannabis flower by size ensures that each bud is used in the most profitable way.

Industry reports indicate an overall average wholesale cannabis flower price of about $900 to $1,000 per pound nationwide; however, this average includes various quality grades and does not isolate A or B buds specifically. Recent trends show fluctuating prices influenced by regulatory changes, oversupply in certain states, and evolving consumer preferences, making precise sorting even more critical for cultivators aiming to maximize their returns.

A Buds (Premium/Top-Shelf Buds)

A buds are the largest and most visually appealing flowers, typically harvested from the colas of the plant. These large buds contain the highest concentration of cannabinoids and terpenes, making them the most desirable option for premium consumers.

Market and Wholesale Pricing: Due to their superior quality, A buds command premium prices in both wholesale and retail markets. Retail consumers typically pay between $200 and $350 per ounce or $10 to $25 per gram, reflecting considerable markups compared to wholesale prices. On the wholesale side, A buds often range from $1,500 to $2,500 per pound, varying by region, strain quality, and cultivation methods.

Common Uses: Sold as top-shelf whole flower for premium consumers.

Curing Time: These buds require a longer curing process to preserve their potency and shelf life.

B Buds (Popcorn Buds/Smalls)

B buds, often referred to as popcorn buds, are smaller flowers that grow lower on the cannabis plant. While they contain a solid cannabinoid and terpene profile, these small buds are not as visually appealing as A buds.

Market and Wholesale Pricing: On the retail market, B buds typically sell at a discounted rate, approximately $100 to $200 per ounce, reflecting their position as a budget-friendly alternative. Wholesale prices for B buds generally range from $800 to $1,500 per pound, varying by region and cultivation quality.

Common Uses: These buds are commonly sold as budget-friendly flower and are often used in pre-roll production.

Curing Time: Due to their smaller size, B buds cure more quickly than A buds, making them easier to process at scale.

Micros, Shake, and Trim

Micros, shake, and trim consist of the smallest buds, broken pieces, and plant material left over from processing the larger flowers. While their visual appeal is minimal, these components play an essential role in production chains for extracts, edibles, and pre-rolls.

Market and Wholesale Pricing: On the retail side, shake and trim products are typically not sold directly to consumers. Wholesale pricing for micros, shake, and trim ranges significantly, typically between $200 to $600 per pound, influenced by quality and market supply.

Common Uses: Micros and trim are frequently used for cannabis concentrates, edibles, and lower-grade pre-rolls.

Curing Time: Since they do not need an extensive curing period, these byproducts can be processed quickly to maintain efficiency.

| CATEGORY | DESCRIPTION | MARKET PRICE | COMMON USES | CURING TIME |

| A Buds | Largest and most visually appealing; premium buds harvested from the colas | Highest: $1,500 to $2,500 per pound wholesale ($200-$350/ounce retail) | Whole flower | Longer curing time |

| B Buds | Also called popcorn; smaller, mid-tier buds | Mid-range: $800 to $1,500 per pound wholesale ($100-$200/ounce retail) | Pre-rolls, budget flower | Shorter than A Buds |

| Micros/Shake | Smallest buds, trim/shake | Lowest: $200 to $600 per pound wholesale | Extracts, edibles, pre-rolls | Quick drying |

Why Categorize Cannabis by Bud Size?

Maximize Price Per Pound

Properly sorting cannabis by bud size allows cultivators to maximize their price per pound. When bud sizes are mixed, it reduces the overall value of a batch, while consistent sorting allows for better pricing differentiation, preventing top-quality buds from being undervalued.

- A buds can be sold at a premium as top-shelf flower.

- B buds can be marketed for budget-conscious consumers and for creating pre-rolls.

- Micros, trim, and shake can be allocated strategically for use in pre-rolls, extracts, or edibles.

Match Bud Size to Market Demand

Market demand also plays a significant role in sorting. Dispensaries and consumers expect consistent sizing for quality assurance, and pre-roll manufacturers and extractors prefer uniform inputs to streamline their production processes. By sorting effectively, each product reaches its most profitable use case.

For example, uniform bud sizes present better in packaging, creating a more appealing and professional look that attracts consumers and encourages repeat purchases. Similarly, extractors benefit from consistent inputs, as this leads to more predictable yields and quality in concentrates, ultimately contributing to a more efficient and cost-effective production cycle.

Protect Trichome Quality and Streamline Processing

Another key factor to sorting is trichome preservation and processing efficiency. Excessive handling of flower buds can degrade trichomes, reducing potency and quality.

Pre-sorting before trimming and curing minimizes unnecessary movement and handling, keeping trichomes intact and ensuring that similar-sized buds cure evenly. Additionally, sorting before trimming allows for greater control over the trimming process, ensuring consistency in cut and finish. When the flower is pre-sorted and the buds going into the trimmer are more uniform, it results in a consistent trim across each bud. If the flower in the trimmer is of mixed sizes, the trim results may vary with larger flowers being under-trimmed and smaller buds getting over-trimmed.

Pairing pre-sorting with post-trimming sorting enhances efficiency in packaging and extraction workflows. When buds are separated by size before trimming, machines operate more efficiently and produce batches of flower that are uniform in quality and size. This can speed post-trimming quality inspections and sorting, allowing workers to quickly separate premium buds from less visually appealing ones.

Factors to Consider When Sorting Cannabis by Bud Size

Impact on Product Quality and Curing Time

One of the most important factors in sorting is the impact on product quality and curing time. Improper curing — whether under-curing or over-curing — can significantly impact cannabis quality. When batches contain mixed sizes of buds, it is difficult to manage the curing time and may result in larger buds not curing long enough or smaller buds becoming overly dry and brittle.

Larger buds require longer curing times to preserve terpenes and cannabinoids and reduce excess moisture to prevent bud rot, or mold growth. Smaller buds need a faster curing process to maintain their integrity and suitability for extracts or pre-rolls. Properly managing curing times based on bud size ensures that cultivators avoid these pitfalls and deliver a consistently high-quality product.

Role of Equipment in Precise Sorting

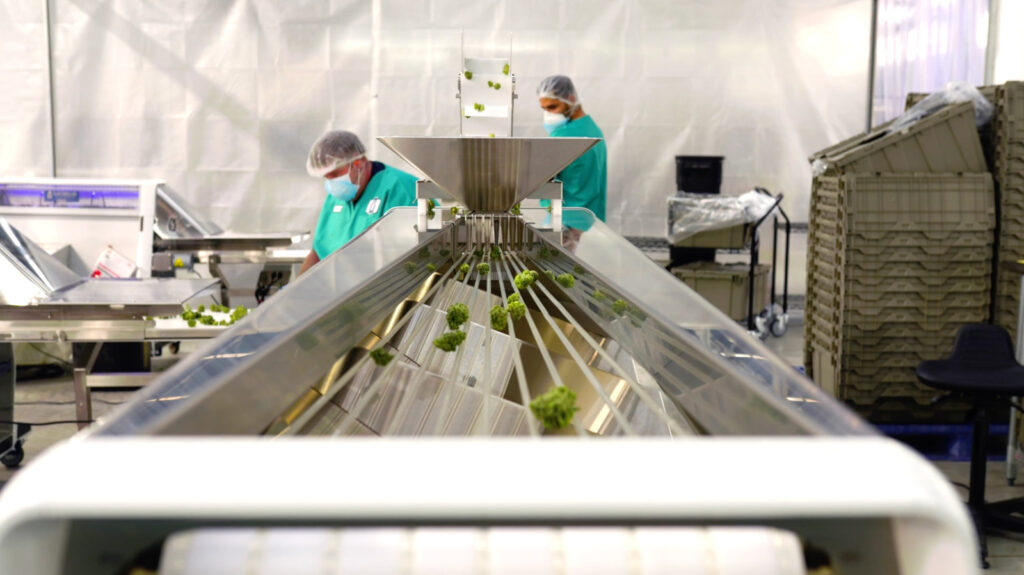

Equipment plays a crucial role in efficient sorting. While manual sorting may be feasible for a smaller, boutique cannabis grower who handles limited volumes, it quickly becomes impractical for larger, commercial-scale operations dealing with substantial harvests.

Sorting cannabis buds manually is labor-intensive, time-consuming, and often inconsistent, leading to potential losses in efficiency and profit margins. Investing in automated sorting systems, such as the Mobius M9 Bud Sorter, significantly improves accuracy, reduces labor costs, and ensures precise size categorization. For large-scale cultivators, automated equipment is not just beneficial — it’s essential to maintaining competitive advantages. Proper sorting enhances downstream processes, from trimming to packaging to extraction, and ensures that each bud reaches its highest potential value.

Automation

Integrating automated conveyors into the sorting process reduces labor costs and significantly improves efficiency and quality control. Mobius’s Autofeed Conveyor, for example, ensures a consistent flow of product into the M9 Bud Sorter, which prevents bottlenecks and maintains optimal sorting accuracy. A steady feed rate reduces manual handling, which will prevent product degradation and preserve trichomes.

Additionally, the autofeed conveyor can be connected to an outfeed conveyor from the trimmer. This provides an opportunity for quality control, allowing operators to inspect the flower post-trimming before it moves to sorting. This step helps identify any inconsistencies, ensuring that only high-quality buds are sorted for packaging or further processing.

Maximize Profits by Sorting Bud Sizes Strategically

Sorting cannabis by bud size is critical for maximizing yield, optimizing pricing, and maintaining product quality. By sorting A buds, B buds, and micros, shake and trim, cultivators can meet market demands, streamline processing, and increase overall profitability. Implementing automated sorting solutions like the Mobius M9 Bud Sorter enhances efficiency and ensures consistent, high-quality results.

Explore the M9 Sorter Today.

Learn more about the Mobius M9 Bud Sorter or contact our team for expert guidance on optimizing your cannabis harvest.